Seattle businesses are rapidly adopting janitorial technology to cut costs and boost efficiency. Smart cleaning systems now reduce labor expenses by up to 30% while improving service quality.

We at Bumble Bee Cleaning Services see companies transforming their operations with IoT sensors, automated scheduling, and precision chemical dispensing. These innovations deliver measurable results that impact your bottom line.

Smart Cleaning Technologies Transforming Seattle Businesses

IoT-Enabled Equipment Monitors Facilities in Real-Time

IoT sensors transform how Seattle companies monitor their facilities. Smart sensors track foot traffic patterns, detect spills within seconds, and measure air quality to trigger targeted responses. By integrating IoT systems with smart process management software, facilities managers can make the data they are already collecting work harder for them.

These sensors connect to central dashboards where facility managers view real-time data about restroom usage, carpet soil levels, and equipment performance. Companies like Microsoft and Amazon have integrated these systems across their Seattle campuses, achieving better efficiency through data-driven decisions.

Automated Software Eliminates Manual Planning

Smart software analyzes historical usage data and weather patterns to predict needs accurately. These systems automatically adjust staff assignments when Seattle’s rainy season increases floor maintenance requirements or when special events boost facility traffic.

Advanced platforms like Building Engines and ServiceChannel integrate with existing facility management systems (providing seamless workflow automation). The software tracks completion times, identifies bottlenecks, and optimizes routes to maximize productivity. Seattle businesses report faster task completion when they use automated systems compared to manual methods.

Precision Dispensers Reduce Chemical Waste

Smart dispensers measure exact chemical amounts based on surface type, soil level, and environmental conditions. These devices connect to management systems to adjust solution strength automatically when air quality sensors detect higher contamination levels.

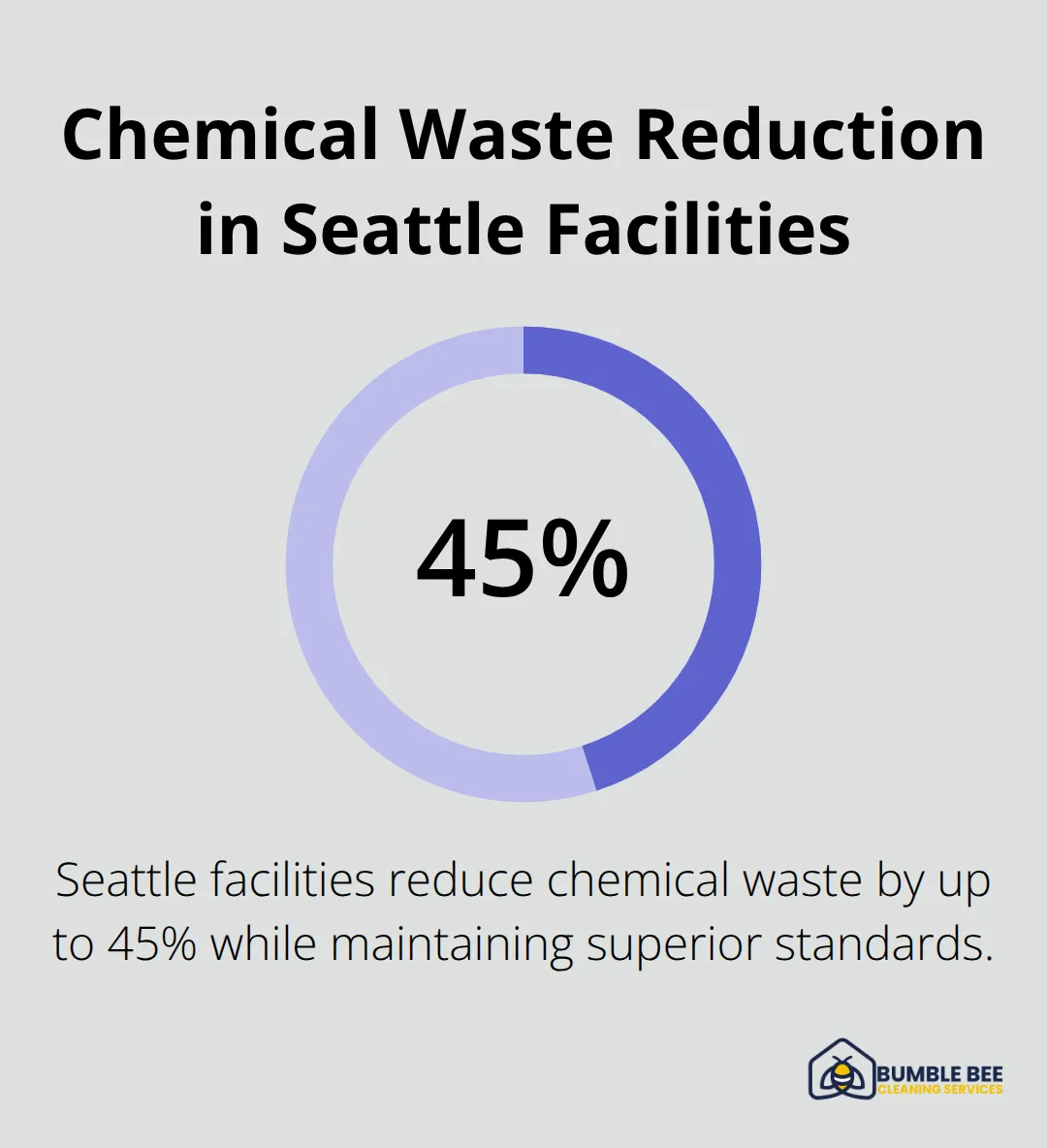

Smart sensors detect areas needing extra cleaning, reducing waste and improving effectiveness. Seattle facilities reduce chemical waste by up to 45% while maintaining superior standards. The systems track usage patterns, alert staff when supplies run low, and generate detailed reports for sustainability compliance (helping businesses meet stringent environmental regulations).

These technological advances create the foundation for significant cost savings and efficiency gains that directly impact your business operations.

Cost Savings and Efficiency Gains from Smart Cleaning

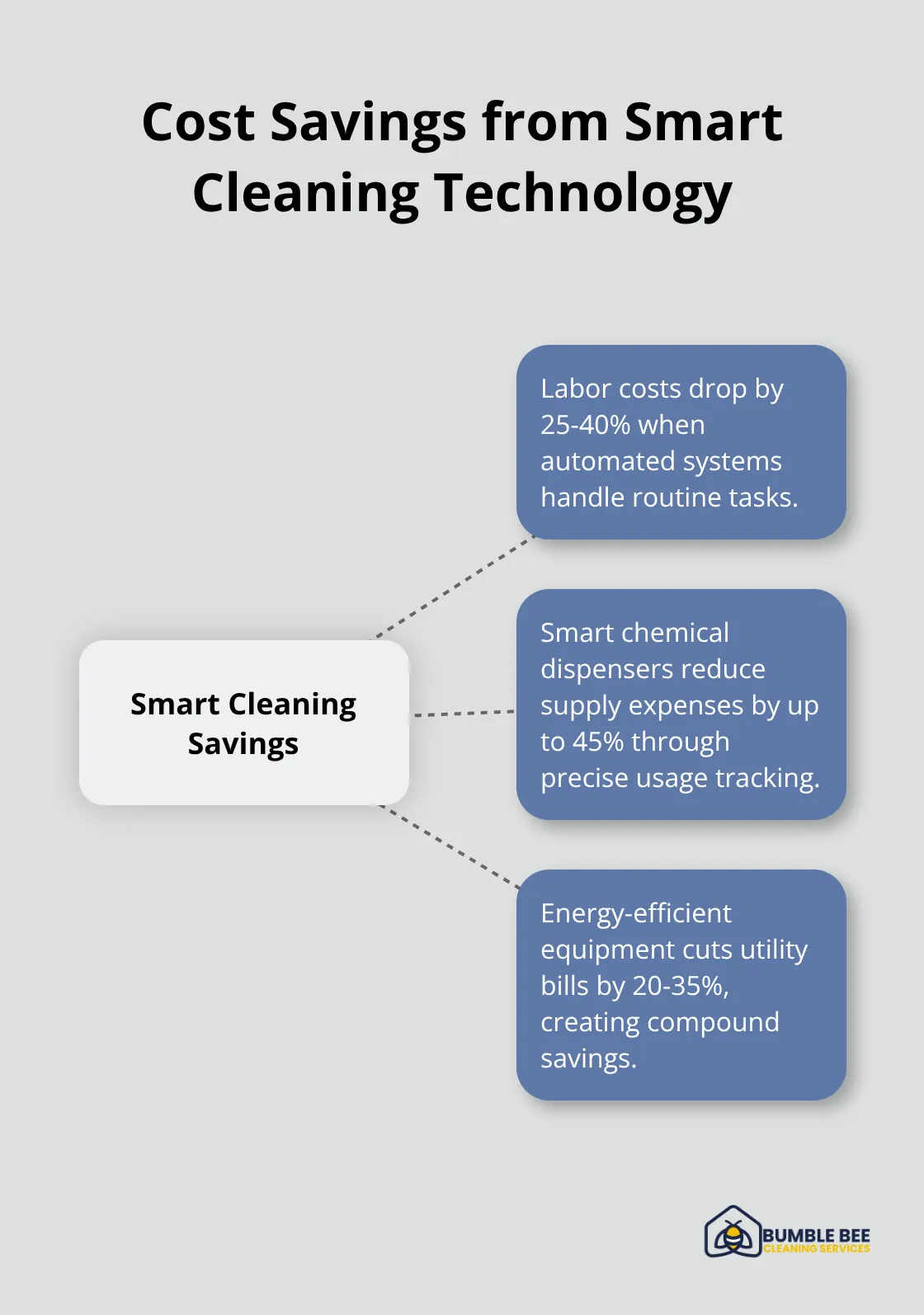

Smart cleaning technology delivers substantial financial returns that transform Seattle business operations. Labor costs drop by 25-40% when automated systems handle routine tasks, while smart chemical dispensers reduce supply expenses by up to 45% through precise usage tracking. Energy-efficient equipment cuts utility bills by 20-35%, creating compound savings that reach six figures annually for mid-sized facilities.

Automation Cuts Payroll Expenses Dramatically

Automated robots handle floor maintenance, restroom checks, and surface sanitization without human supervision. Seattle companies that use robotic systems report labor savings of $150,000-$300,000 per year for facilities over 50,000 square feet. Smart software optimizes staff deployment, eliminates overtime costs, and reduces full-time positions needed.

Companies like Starbucks headquarters in Seattle have cut staff requirements by 35% while they maintain higher cleanliness standards through strategic automation implementation. These systems work around the clock (reducing the need for multiple shifts) and complete tasks faster than traditional methods.

Smart Dispensers Stop Supply Waste

Precision dispensers measure exact chemical amounts based on soil detection sensors and surface requirements. Traditional methods waste 30-50% of chemicals through over-application, while smart systems use only necessary amounts. Seattle facilities track every ounce of solution and generate detailed usage reports that identify waste patterns.

Smart inventory management prevents stockouts and bulk purchase inefficiencies, which reduces supply costs by $50,000-$100,000 annually for large commercial spaces. These systems alert managers when supplies run low and automatically reorder products at optimal quantities.

Energy Management Reduces Utility Bills

Smart equipment operates during off-peak hours when electricity rates drop 40-60% below daytime costs. IoT sensors automatically shut down unused equipment, while energy-efficient motors in robotic cleaners reduce energy consumption through advanced motor and drive technology. Seattle businesses that implement comprehensive smart systems see monthly utility reductions of $5,000-$15,000.

Payback periods typically fall under 18 months for initial technology investments (making the transition financially attractive for most facilities). These savings compound over time as equipment becomes more efficient and energy costs continue to rise.

Smart cleaning technology creates measurable financial benefits, but successful implementation requires careful planning and the right strategic approach for your specific business needs.

Implementation Strategy for Seattle Companies

Start with a comprehensive facility audit that maps current labor hours, chemical usage patterns, and equipment performance across all areas. Document baseline metrics that include square footage cleaned per hour, supply costs per room, and energy consumption by zone. Seattle facilities that skip this step face increased costs during implementation because they cannot measure improvement or identify problem areas. Track staff time allocation for two weeks minimum to understand workflow bottlenecks and inefficient processes.

Assess Your Current Operations First

Measure existing performance across all facility zones before you introduce new technology. Record how much time staff spend on each task, which areas require the most attention, and where supply waste occurs most frequently. Document energy usage patterns during peak and off-peak hours to identify optimization opportunities. This baseline data helps you calculate return on investment and proves the value of smart technology to stakeholders.

Choose Technology Partners with Local Support

Select vendors with Seattle-based technical support teams and proven installation records in Pacific Northwest facilities. Look for companies that maintain regional service centers for quick response to equipment issues. Avoid vendors without local presence because remote troubleshooting delays can cost significant productivity losses. Request client references from similar Seattle businesses and visit their facilities to see systems in action.

Train Staff Through Hands-On Practice

Implement 40-hour programs that combine classroom instruction with supervised equipment operation. Staff training retention improves by 35% when workers feel confident with new technology rather than threatened by automation. Create skill-based pay increases of $2-$4 per hour for employees who complete advanced system certifications (which motivates participation and reduces turnover). Schedule sessions during slow periods to maintain service levels.

Manage the Technology Transition Gradually

Replace traditional methods over 60-90 days to prevent service disruptions while staff build confidence with new systems. Assign tech-savvy employees as peer mentors for colleagues who need extra support. Start with less complex areas like lobbies and conference rooms before moving to high-traffic zones. Monitor performance metrics weekly during the transition period and adjust timelines based on staff comfort levels and system performance.

Final Thoughts

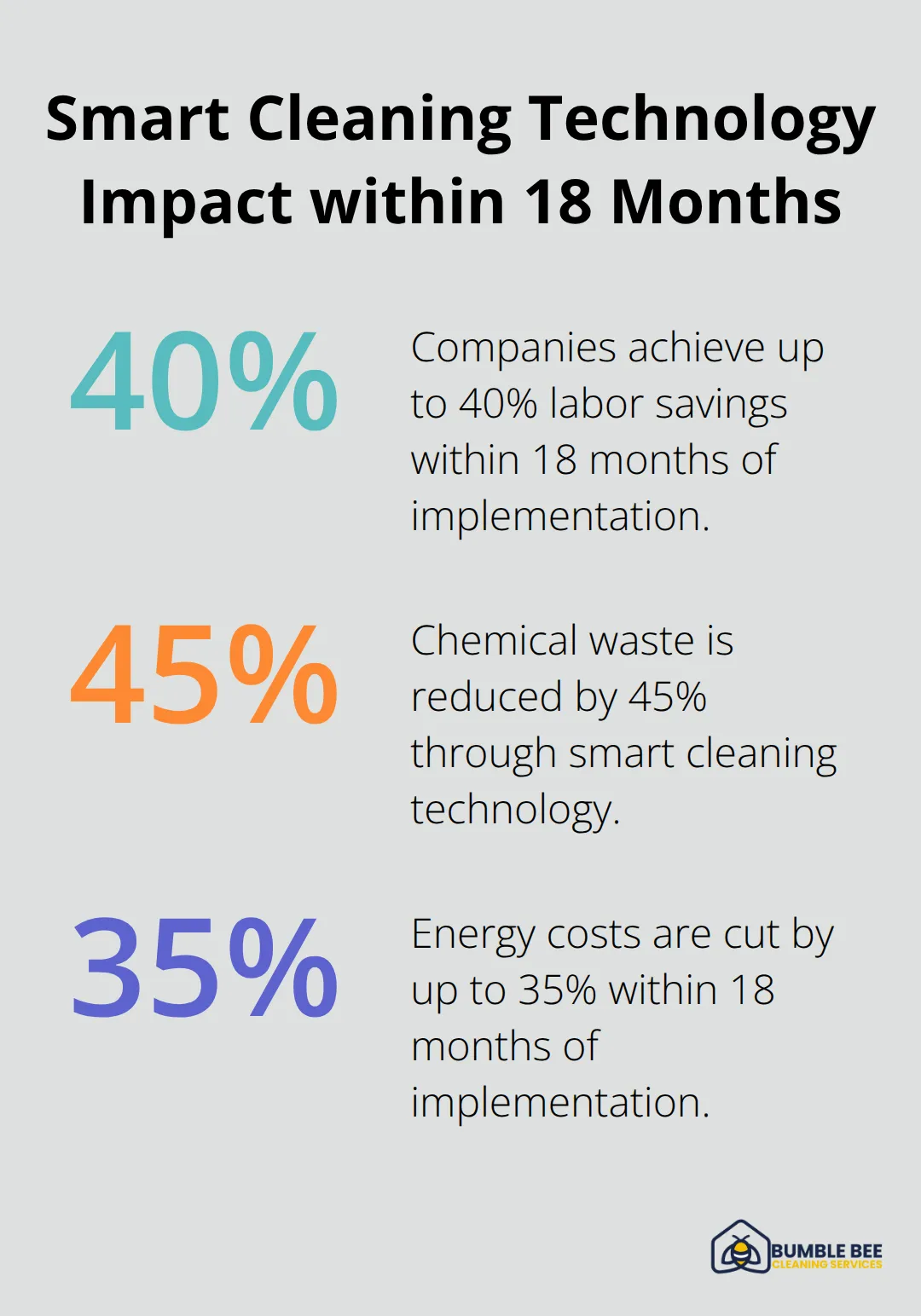

Smart cleaning technology transforms Seattle businesses through measurable cost reductions and operational improvements. Companies achieve 25-40% labor savings, reduce chemical waste by 45%, and cut energy costs by 20-35% within 18 months of implementation. These systems deliver compound benefits that reach six-figure annual savings for mid-sized facilities.

Janitorial technology creates competitive advantages beyond cost savings. Automated systems maintain consistent quality standards while they free staff for higher-value tasks. Real-time sensors prevent problems before they impact operations, and data-driven insights optimize resource allocation across all facility areas.

Seattle businesses ready to modernize their operations should start with comprehensive facility assessments and partner selection. We at Bumble Bee Cleaning Services help Seattle companies navigate this transformation with our commercial cleaning solutions. Smart systems support sustainability goals through reduced waste and energy consumption while they create healthier work environments (which boost productivity and employee satisfaction).