Manufacturing cleanup isn’t a job for standard commercial cleaners. The residue, hazardous materials, and regulatory demands in industrial facilities require teams with specialized training and equipment.

We at Bumble Bee Cleaning Services understand that one wrong move can create safety risks, compliance violations, and costly downtime. That’s why this guide walks you through what makes industrial cleaning different and why hiring the right team matters.

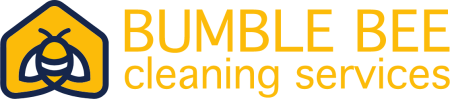

What Actually Contaminates Manufacturing Facilities

Industrial Residue That Damages Equipment and Inventory

Manufacturing facilities accumulate contamination that standard office cleaning cannot address. Dust and debris infiltrate cooling systems and equipment filters, accelerating wear and raising maintenance costs while risking unexpected downtime. Metal shavings, oil residue, chemical compounds, and particulate matter settle on surfaces and inside machinery, rendering products unsellable when they contaminate inventory. Food manufacturing facilities face additional pressure from the Seattle Food Code, which enforces strict cleaning protocols for food-contact surfaces. These contaminants don’t just sit on surfaces-they actively degrade your equipment and destroy your bottom line.

Safety Hazards That Injure Workers

Poor sanitation creates slip-and-fall hazards that injure workers across U.S. warehouses. According to the Washington State Department of Labor & Industries, contamination on floors and walkways poses immediate danger to your team. High-touch surfaces in manufacturing environments-forklift handles, control panels, equipment interfaces, door handles-demand hospital-grade, EPA-approved disinfectants applied strategically rather than indiscriminate spraying that wastes resources and fails to protect workers. OSHA sanitation guidelines require you to disinfect these surfaces regularly to prevent cross-contamination and reduce workplace illness.

Regulatory Violations and Compliance Risks

Poor sanitation triggers regulatory violations that carry steep fines and forced shutdowns. The King County Board of Health Code governs sanitation standards for non-food manufacturing spaces in Seattle, making compliance non-negotiable for operations in this region. Mishandling hazardous materials exposes your operation to liability, fines, and environmental violations that damage your reputation with clients and regulators alike.

Seattle’s Climate and Specialized Contamination Challenges

Seattle’s damp climate compounds these challenges by creating moisture-related risks like mold growth, which requires specialized moisture control and vent inspection that general cleaners lack the expertise to handle. Manufacturing teams also generate hazardous waste streams including chemical solvents, used oils, electronic waste, and contaminated materials that cannot enter standard garbage collection and demand certified hazardous waste disposal through specialized services. Your facility’s specific waste streams determine which disinfectants and disposal methods apply, making it clear that one-size-fits-all cleaning approaches fail in industrial settings.

Why Standard Cleaners Miss the Mark in Manufacturing

Equipment That Doesn’t Match Industrial Demands

Standard commercial cleaning companies operate under fundamentally different assumptions than manufacturing facilities demand. Their teams train on office protocols, retail environments, and standard commercial spaces where the worst contamination involves dust and surface grime. Manufacturing environments generate metal shavings, chemical residues, oil buildup, and particulate matter that require specialized extraction equipment, containment strategies, and disposal protocols that general cleaners simply don’t own or understand.

When a standard cleaning crew arrives at your facility, they bring vacuum cleaners rated for carpet and tile, microfiber cloths, and off-the-shelf disinfectants. None of these tools address industrial contamination. Oil residue won’t lift with standard degreasers. Metal particulates won’t stay contained in a regular vacuum filter. Chemical compounds require specific neutralization procedures that vary by substance, concentration, and surface type.

A general cleaner treating all contaminants the same way wastes time, fails to remove hazards, and leaves your equipment at risk.

Training Gaps That Create Compliance Exposure

The training gap runs deeper than equipment. Standard commercial cleaners receive orientation on cleaning schedules, customer service, and basic safety. Manufacturing-grade cleaning demands knowledge of OSHA regulations specific to industrial spaces, EPA-approved disinfectant protocols for high-touch surfaces, and hazardous waste classification under Washington State Department of Ecology guidelines.

Your facility likely generates waste streams including spent solvents, contaminated oils, electronic waste, and chemical byproducts that cannot enter standard garbage collection. Certified hazardous waste disposal requires documentation, tracking, and partnerships with licensed disposal facilities that general cleaners neither maintain nor understand. The Seattle Food Code adds another layer if you handle food products, mandating specific disinfectants and cleaning frequencies on food-contact surfaces. General cleaners don’t maintain current certifications in these areas, don’t track regulatory updates, and don’t carry liability insurance covering industrial contamination incidents.

Why Certification and Insurance Matter

When OSHA inspects your facility and finds inadequate disinfection protocols or improper waste handling, the liability falls on you, not the cleaner you hired. Specialized manufacturing cleanup teams carry ARCSI and IICRC certifications demonstrating they stay current on contamination-control standards, maintain proper insurance, and follow documented protocols that satisfy regulatory audits. The cost difference between a general cleaner and a specialized team reflects this gap in expertise, liability protection, and compliance capability. This distinction becomes important when you face regulatory scrutiny or contamination incidents that expose your operation to fines and shutdowns.

What Specialized Teams Actually Deliver

Certified manufacturing cleanup teams bring capabilities that standard commercial cleaners simply cannot match. Your facility needs technicians trained in industrial contamination protocols, not general janitorial staff. Specialized teams stay current on EPA disinfectant standards and OSHA sanitation requirements, and Washington State Department of Ecology hazardous waste classifications because these certifications directly prevent your operation from facing violations, fines, and shutdowns. When you hire a specialized team, you’re paying for documented expertise that protects your bottom line, not just for someone with a mop and standard disinfectant.

The Equipment Difference That Matters

Industrial cleanup demands extraction equipment designed for heavy contamination. Specialized teams deploy HEPA-filtered vacuum systems that contain metal particulates, oil-laden dust, and chemical residues without spreading them through your facility or into standard garbage streams. They carry pressure washers rated for degreasing concrete floors contaminated with hydraulic oils and coolants-equipment that removes buildup standard floor cleaners leave behind. High-touch surface disinfection uses hospital-grade, EPA-approved products applied with electrostatic spraying technology that ensures complete coverage on forklift handles, control panels, and door handles without the waste and incomplete protection of indiscriminate spraying. Post-construction cleaning in manufacturing spaces requires specialized dust containment systems and air scrubbers that prevent newly renovated areas from introducing contamination into active production zones. General cleaning companies lack this equipment entirely because their market doesn’t demand it.

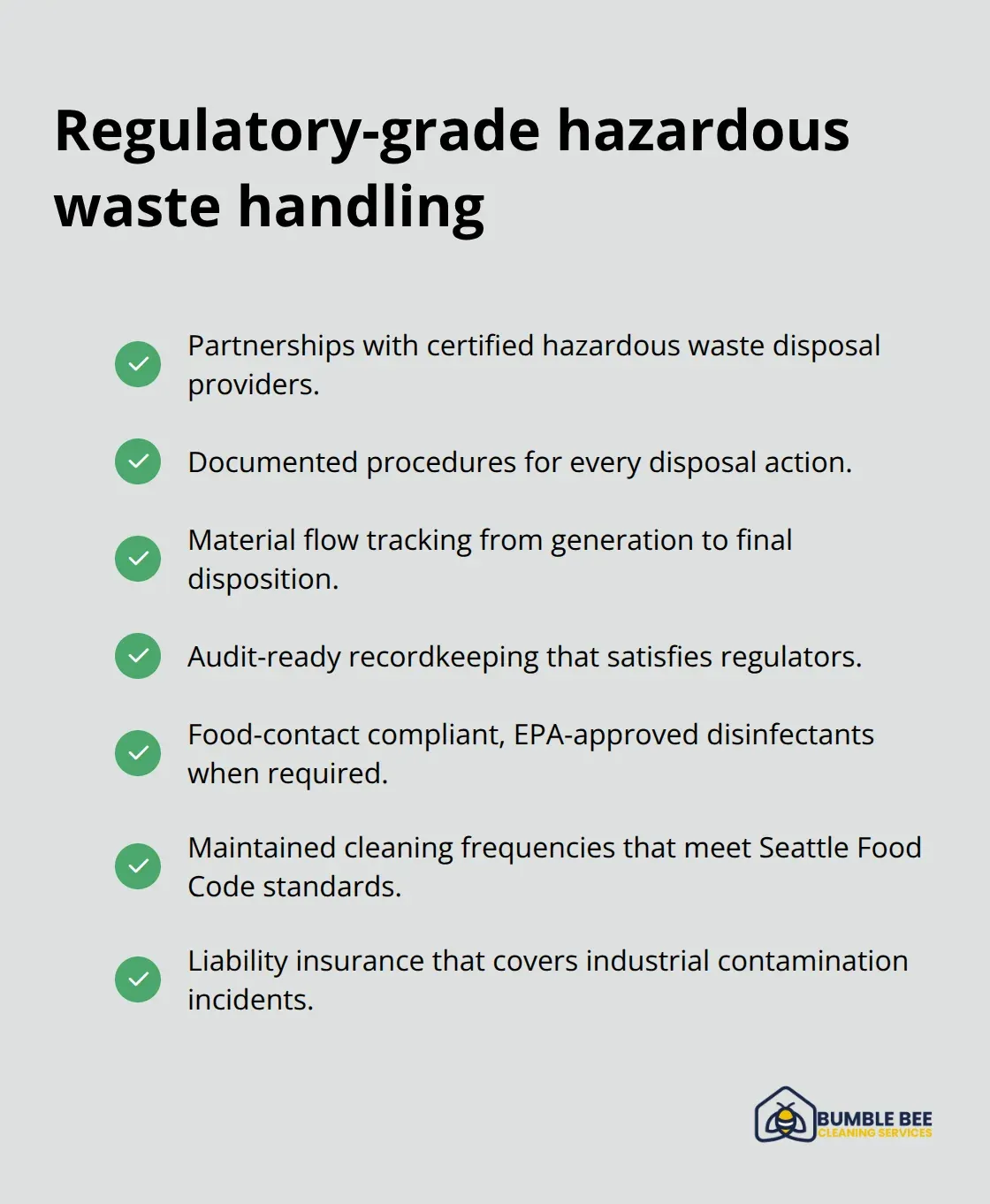

Hazardous Waste Handling and Regulatory Navigation

Manufacturing facilities generate spent solvents, contaminated oils, electronic waste, and chemical byproducts that cannot enter standard garbage collection without triggering regulatory violations. Specialized cleanup teams maintain partnerships with certified hazardous waste disposal providers and understand Washington State Department of Ecology classification requirements for your specific waste streams. They document disposal procedures, track material flows, and maintain records that satisfy regulatory audits. When your facility handles food products under Seattle Food Code guidelines, specialized teams know which EPA-approved disinfectants work on food-contact surfaces and maintain cleaning frequencies that meet compliance standards.

General cleaners neither understand these distinctions nor carry the liability insurance covering industrial contamination incidents.

Certifications That Protect Your Operation

ARCSI and IICRC certifications demonstrate that specialized teams stay current on contamination-control standards, maintain proper insurance, and follow documented protocols that satisfy regulatory audits. These credentials matter because OSHA inspectors expect your facility to employ cleaners who understand industrial sanitation requirements. When violations occur, the liability falls on you, not the cleaner you hired. Specialized teams carry documentation proving they meet these standards, protecting your operation during regulatory inspections. General cleaners operate without these certifications and cannot provide the liability protection your manufacturing facility needs.

Final Thoughts

Manufacturing cleanup demands expertise that goes beyond standard commercial cleaning. Your facility faces contamination risks, regulatory exposure, and equipment damage that only specialized teams can address effectively. The gap between general cleaners and industrial specialists isn’t minor-it’s the difference between compliance and violations, between equipment longevity and costly breakdowns, between worker safety and preventable injuries.

Hiring specialized manufacturing cleanup teams delivers measurable returns. Your equipment lasts longer when professionals remove metal particulates and oil residue before they infiltrate cooling systems. Your inventory stays sellable when contamination protocols prevent dust and debris from rendering products unsellable. Your workers stay safer when high-touch surfaces receive hospital-grade disinfection rather than indiscriminate spraying.

We at Bumble Bee Cleaning Services bring specialized experience and ARCSI and IICRC certifications to manufacturing facilities across Seattle. Our team understands the demands of industrial contamination control, hazardous waste handling, and regulatory compliance specific to your operation. Contact us today to learn how professional manufacturing cleanup protects your operation, your workers, and your bottom line.