New Seattle buildings often hide a dirty secret behind their pristine facades. Construction dust, debris, and contaminants settle deep within HVAC systems during the building process.

We at Bumble Bee Cleaning Services see this problem daily across Seattle’s booming construction market. Professional ventilation cleaning becomes essential before occupancy to protect indoor air quality and system performance.

Why New Seattle Buildings Need Immediate Ventilation Cleaning

The National Association of Home Builders reports that construction generates 8,000 pounds of waste material per 2,000 square foot home. This debris doesn’t just disappear – much of it settles directly into your building’s HVAC system. Construction workers often run heating and cooling systems during the building process, which pulls drywall dust, sawdust, insulation fibers, and metal shavings through ductwork. The Indoor Air Quality Association emphasizes that construction dust continues to circulate through buildings long after construction ends, which creates ongoing contamination issues.

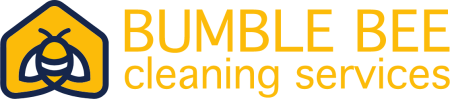

Construction Debris Accumulates in HVAC Systems

Construction activities produce massive amounts of particulate matter that infiltrates ventilation systems. Workers cut materials, sand surfaces, and demolish structures while HVAC systems operate to maintain comfortable working conditions. These systems act like giant vacuum cleaners, sucking construction debris through intake vents and distributing it throughout the entire ductwork network.

Fine particles settle in hard-to-reach areas of ducts, coils, and filters where they remain trapped for months or years.

Seattle’s Moisture Creates Perfect Storm for Contamination

Seattle’s humid climate transforms construction dust into a breeding ground for mold and bacteria. When moisture meets the debris trapped in your ventilation system, you get rapid microbial growth that spreads throughout the building. The Environmental Protection Agency documented that 600 million tons of construction debris were generated nationwide in 2018, with Seattle’s wet climate making contamination worse than drier regions (particularly during our extended rainy seasons). Your new building’s HVAC system becomes a distribution network for these contaminants, which pushes polluted air into every room.

Construction Dust Contains Dangerous Materials

Construction environments expose occupants to silica dust, asbestos particles from older building materials, and volatile organic compounds from adhesives and paints. OSHA identifies construction dust as containing harmful substances that pose serious respiratory risks. The average indoor air in new buildings can be several times more polluted than outdoor air without proper ventilation cleaning. Workers and future occupants face increased risks of respiratory problems, allergies, and long-term health complications from breathing contaminated air that circulates through dirty ductwork systems.

These contamination issues don’t resolve themselves over time – they require professional intervention to identify and address properly.

Signs Your New Building’s Ventilation System Needs Professional Cleaning

Smart building owners watch for specific indicators that reveal contamination problems in their HVAC systems. These warning signs appear within weeks of construction completion and worsen rapidly without professional intervention.

Visible Dust and Debris Around Vents and Registers

Heavy dust buildup around air vents and registers signals serious contamination inside your ductwork. When you see thick layers of construction debris that coat vent covers, the same material fills your entire ventilation system. Fine particles continuously blow from supply vents and settle on furniture and surfaces throughout the building.

Buildings with visible dust accumulation around vents contain significantly more debris inside their ductwork. Check your air filters monthly – new buildings with contaminated systems require filter changes every 2-3 weeks instead of the standard 90 days. Clogged filters force your HVAC system to work harder, which can lead to increased energy costs.

Poor Air Quality and Unusual Odors Throughout the Building

Poor indoor air quality manifests through persistent odors, stuffiness, and respiratory complaints from occupants. Construction materials release volatile organic compounds that create chemical smells lasting months after completion. Musty odors indicate moisture has activated mold growth in contaminated ductwork.

Americans spend 90% of their time indoors, meaning occupants breathe contaminated air constantly in poorly maintained buildings. Tenant complaints about headaches, throat irritation, and breathing difficulties spike in new buildings with dirty ventilation systems.

HVAC System Performance Issues and Increased Energy Costs

Energy costs increase when HVAC systems struggle against clogged components and restricted airflow from construction debris. Your system runs longer cycles to maintain desired temperatures, which puts excessive strain on equipment and shortens its lifespan. Uneven temperature distribution across floors indicates blocked ducts or contaminated components that prevent proper air circulation.

Professional assessment becomes necessary when these performance issues persist beyond the first month of operation (as temporary problems typically resolve themselves quickly). Post-construction cleanup should include thorough HVAC system cleaning to prevent these costly complications.

Professional Ventilation Cleaning Process for New Buildings

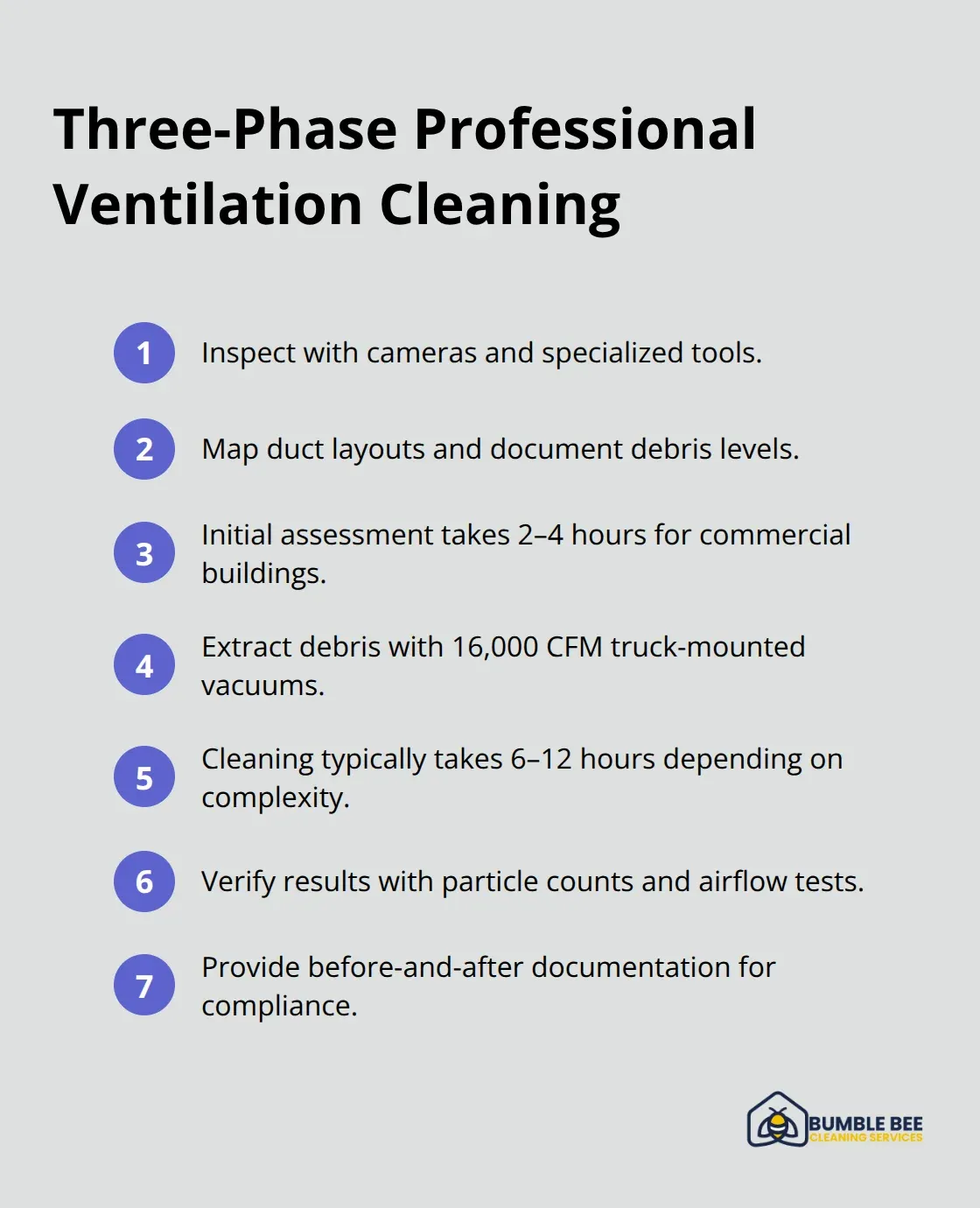

Professional ventilation cleaning for new buildings follows a systematic three-phase approach that removes construction debris and restores air quality. The process begins with comprehensive inspection that uses cameras and specialized tools to assess contamination throughout the entire HVAC system. Technicians map ductwork layouts, identify problem areas, and document debris accumulation levels before they start any work. This initial assessment typically takes 2-4 hours for commercial buildings and reveals hidden damage or blockages that could affect system performance.

Pre-Inspection Assessment Reveals Hidden Problems

Certified technicians use video inspection equipment to examine every section of ductwork and identify specific contamination types. The NADCA Standard outlines necessary procedures for inspecting HVAC systems and provides guidelines for determining when these services are needed. Inspectors check for disconnected joints, damaged insulation, and moisture intrusion that could compromise effectiveness. Buildings constructed in Seattle’s wet climate require special attention to moisture-related issues that accelerate mold growth in contaminated systems.

Specialized Equipment Extracts Construction Debris

Professional teams deploy truck-mounted vacuum systems that generate 16,000 cubic feet per minute of suction power to extract heavy construction debris from ductwork. These powerful systems remove materials that standard residential equipment cannot handle (including metal shavings, drywall chunks, and dense insulation fibers). Technicians use brushes, compressed air tools, and agitation devices to dislodge stubborn debris from duct walls and coil surfaces. The process takes 6-12 hours for typical commercial buildings depending on system complexity and contamination levels.

Post-Cleaning Verification Confirms System Performance

Professional services complete the process with air quality tests and photographic documentation that proves cleanliness standards. Technicians measure particle counts, verify proper airflow rates, and test for microbial contamination through laboratory analysis. Seattle building codes increasingly require certification of indoor air quality before occupancy permits are issued (making this step mandatory for many projects). Professional companies provide detailed reports that document before-and-after conditions, which building owners need for warranty compliance and tenant health protection.

Final Thoughts

Professional ventilation cleaning protects your investment and occupant health in new Seattle buildings. Construction debris trapped in HVAC systems creates ongoing contamination that worsens over time without proper intervention. Clean air systems reduce energy costs by 15-20% while they extend equipment lifespan and prevent costly repairs.

Building owners who prioritize ventilation cleaning see immediate improvements in tenant satisfaction and reduced maintenance calls. Clean systems prevent mold growth that thrives in Seattle’s humid climate and eliminate health risks from construction dust circulation. Professional cleaning also maintains warranty compliance for HVAC equipment manufacturers who require proper maintenance protocols.

We at Bumble Bee Cleaning Services recommend that you schedule professional assessment within 30 days of construction completion (before occupants move in). Our team provides comprehensive post-construction cleaning services that address both visible surfaces and hidden HVAC contamination. Building managers should establish annual maintenance schedules to preserve air quality and system performance long-term.