Running a food service operation in Seattle means staying on top of health codes, cleaning protocols, and daily sanitation routines. One missed inspection or overlooked cleaning task can cost you thousands in fines and damage your reputation.

We at Bumble Bee Cleaning Services have helped dozens of Seattle restaurants build cleaning systems that actually work. This guide walks you through the exact standards you need to meet, the deep cleaning methods that matter, and how to create schedules your team will follow.

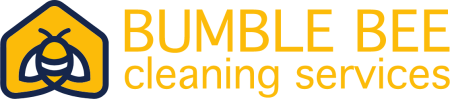

What Seattle Health Inspectors Actually Look For

Inspection Schedules and Violation Consequences

Seattle’s food service regulations come from the Washington State Department of Health, and they’re not suggestions. The Public Health-Seattle & King County Food Protection division conducts unannounced inspections on a schedule that depends on your establishment type and risk level. High-risk facilities like full-service restaurants face inspections every 6 to 12 months, while lower-risk operations receive visits less frequently. When violations appear, the consequences hit immediately and hard. Minor violations result in fines ranging from hundreds to thousands of dollars, but serious issues like improper food storage or pest infestations can trigger temporary closures that devastate revenue. The King County Environmental Health Services publishes inspection ratings online, and these ratings directly influence customer perception-an unfavorable rating is visible to anyone searching your establishment’s name.

Using Inspection Data to Strengthen Your Protocols

You can access the actual inspection data through King County’s open data portal, which shows exactly what violations other restaurants in your area received. This information gives you actionable intelligence. If you see that three competitors received citations for inadequate sanitizer contact times or grease buildup in hood systems, you know exactly what to prioritize in your own cleaning protocols. The violations that appear most frequently in your neighborhood reveal the specific weak points that inspectors target. Rather than guessing what matters most, you work from real data about what actually fails inspections in Seattle restaurants.

Documentation Separates Compliant Operations from Risky Ones

Health inspectors spend most of their time examining your records, not just your surfaces. You need dated logs showing when food arrived, when staff cooked it, when it left the kitchen, and when expired items went out. Temperature logs for refrigerators and freezers matter enormously-inspectors check these first because they directly prevent foodborne illness. Cleaning schedules with staff signatures and records of sanitizer strength testing all separate restaurants that pass easily from those that scramble during inspections. The transition to Washington’s new permitting system as of late 2025 means your documentation practices must align with updated requirements, so verify current standards directly with the Food Protection division rather than relying on older guidance.

Window Signage and Internal Records

Window signage displaying your health rating sometimes lags behind your actual current rating, which means maintaining meticulous internal records protects you if a customer sees an older rating posted. A detailed cleaning log that documents which surfaces you sanitized, when you sanitized them, and which products you used gives you proof of compliance if violations are questioned. This documentation becomes your defense during inspections and your evidence that your team follows established protocols consistently. With these records in place, you move from reactive compliance to proactive management-you demonstrate that violations don’t happen because of carelessness, but because your systems catch and correct issues before inspectors arrive.

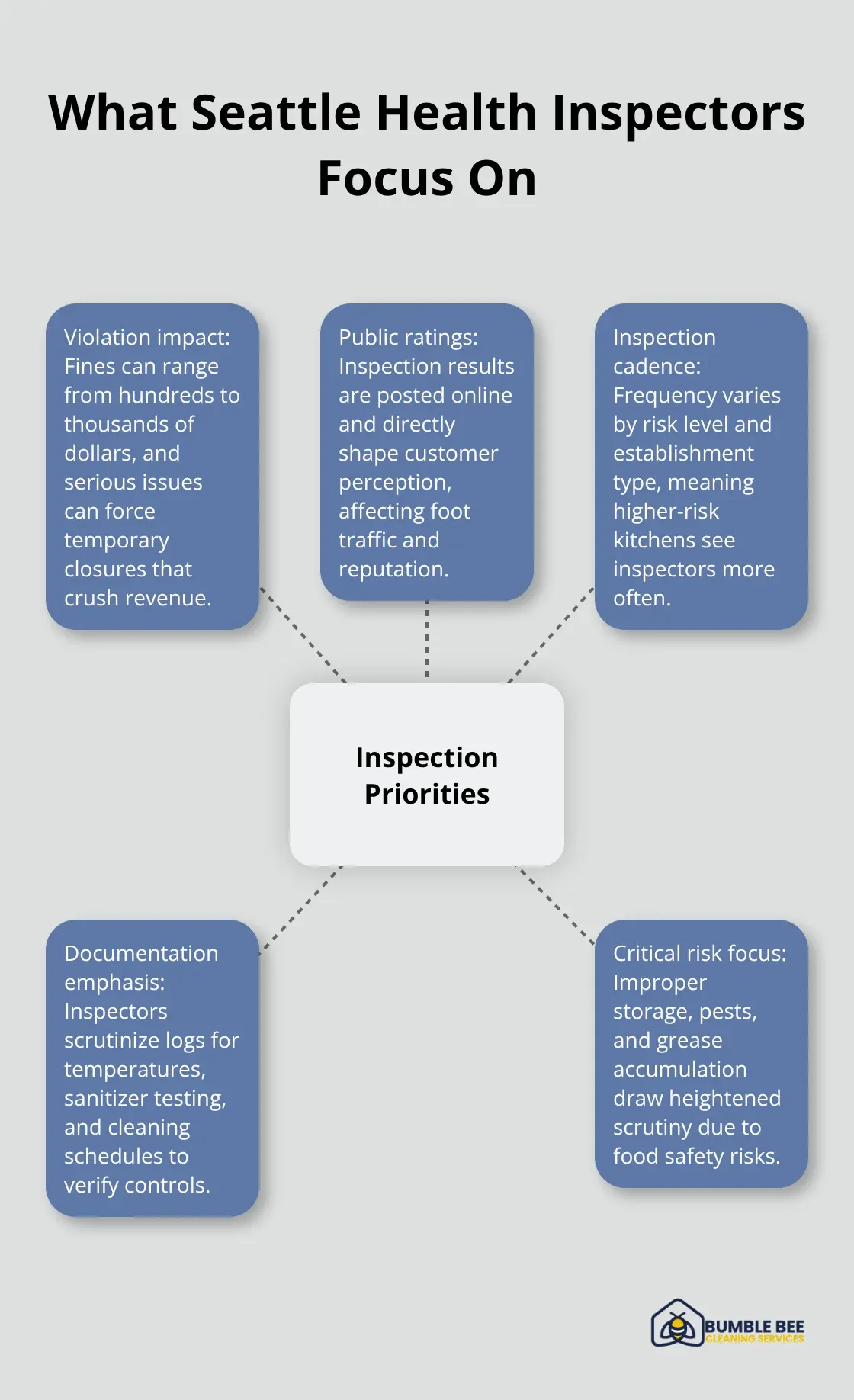

Deep Cleaning Protocols for Kitchen Equipment

Your hood system, fryers, and grills represent the highest-risk areas in your kitchen during health inspections. Inspectors spend disproportionate time examining these surfaces because grease buildup, improper sanitization, and temperature control failures at this equipment directly cause violations. Grease traps and hood exhaust systems are where most Seattle restaurants lose points-the Canadian Institute of Food Safety identifies kitchen equipment and utensils as primary cross-contamination sources, and accumulated grease creates an environment where bacteria thrive. When you neglect the space behind your stove, under your fryer basket, or inside your hood filters, you build a violation waiting to happen.

Weekly and Monthly Equipment Maintenance

Deep clean these specific areas monthly at minimum, not occasionally when you remember. Your fryer requires a complete boil-out weekly to remove accumulated oil residue that sanitizers alone cannot penetrate. Your grill and griddle need scraping between uses during service, then a thorough degrease weekly using commercial-grade degreasers designed for high-heat surfaces. The hood and exhaust fans collect grease at an alarming rate-quarterly professional duct cleaning prevents the kind of buildup that triggers automatic violations.

Floors and Walls in High-Risk Zones

Floors and walls in the back-of-house demand attention in specific zones: behind equipment, under the line, and in storage areas where moisture accumulates. These aren’t glamorous spots, but inspectors look here because they reveal whether your team performs cleaning tasks consistently or only when visible. Mop your floors daily with appropriate floor-care products, but also allocate time monthly to clean beneath large equipment-under and behind your refrigerators, under prep tables, and in the corners where your mop cannot reach.

Degreasing Walls and Surfaces

Grease buildup on walls behind your cooking line requires monthly attention using a degreaser and cloth, not just water. Your walk-in refrigerators and freezers need sanitizing with detergent-sanitizer solution monthly, and the anti-fatigue mats underneath should be washed weekly to prevent bacterial growth in the moisture that accumulates beneath them. Temperature control matters enormously here-ensure your thermometers are accessible and your temperature logs are dated and visible.

Documentation Paired with Physical Cleanliness

This documentation, paired with a physically clean environment, demonstrates to inspectors that you understand both food safety science and practical execution. Your team’s ability to maintain these standards consistently separates restaurants that pass inspections easily from those that scramble to address violations. The daily cleaning schedule you establish determines whether your kitchen stays compliant throughout the year or faces surprises during unannounced visits. With these protocols in place, you’re ready to build the daily systems that keep your team accountable and your kitchen inspection-ready.

How to Build a Daily Cleaning Schedule Your Team Actually Follows

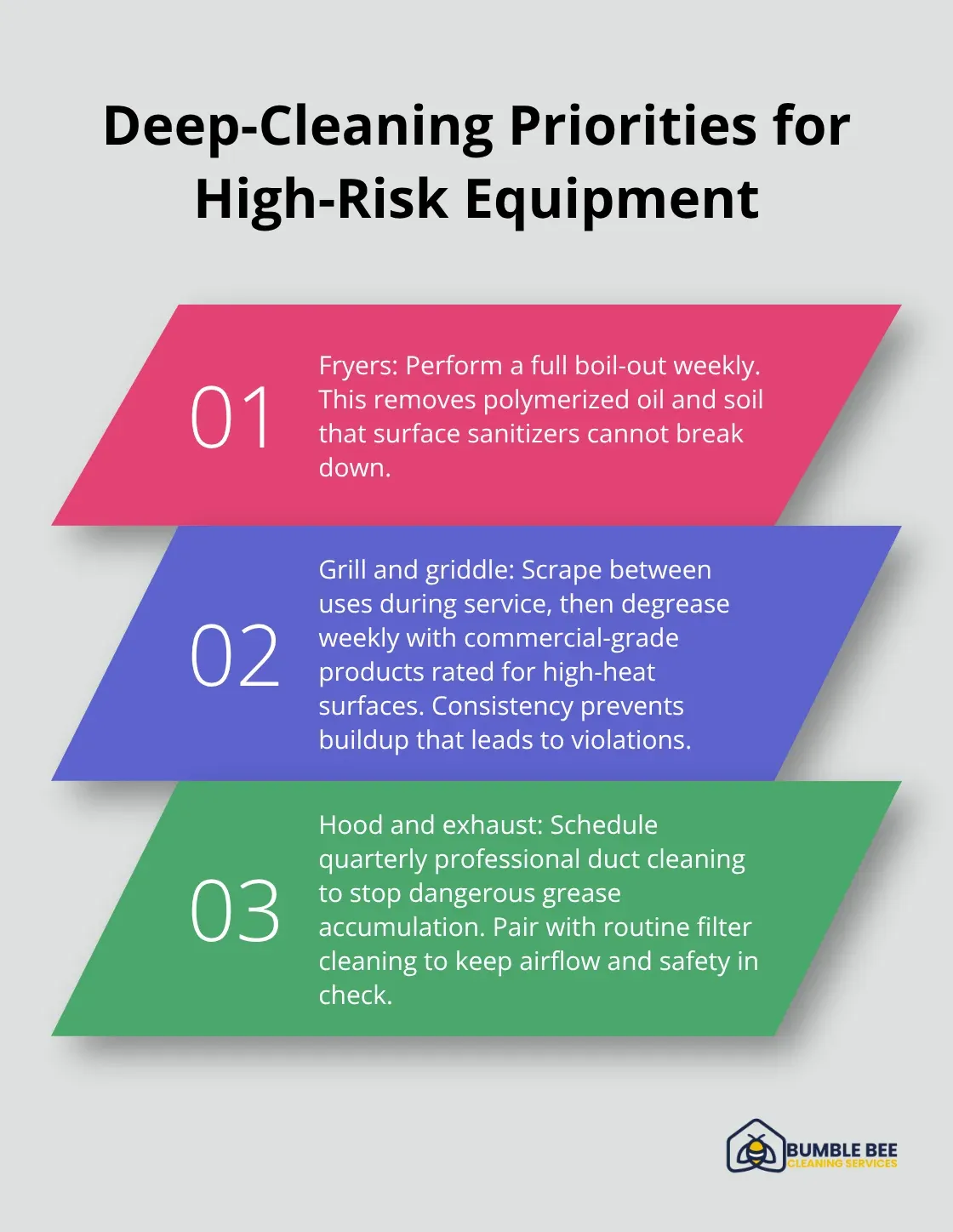

Morning Prep Area Sanitation

Your morning prep area sets the tone for everything that happens during service. Start with sanitized surfaces before any food touches them. Wipe down prep tables with surface sanitizing chemicals, clean cutting boards with a vinegar solution between different food types, and verify that all utensils have air-dried overnight from the previous shift. This matters because cross-contamination from wet surfaces and shared tools causes more violations than almost any other factor. Check your sanitizer strength with test strips before you begin-many Seattle restaurants fail inspections because staff dilute sanitizers incorrectly or use products beyond their effective contact time. Your team needs proper sanitizer contact time for most commercial sanitizers to work, which means spraying a surface and wiping it immediately defeats the purpose.

Post the contact time requirement visibly at each prep station so no one guesses. Clean beverage dispensers, soda gun tips, and coffee maker heads daily because bacteria accumulate in these moist environments faster than anywhere else in your kitchen. Refill soap dispensers and paper towel rolls before your shift starts, not when staff run out mid-service.

End-of-Shift Equipment Breakdown

End-of-shift cleaning determines whether violations pile up or stay controlled. Your line cooks should empty drip trays from grills and griddles, clean microwave interiors, and wipe down the vent hood filters-these tasks take fifteen minutes and prevent the grease accumulation that triggers automatic violations. The dish pit requires hand-washing items the machine cannot handle, then cleaning sinks thoroughly and mopping floors to prevent bacterial growth in standing water. Assign one person ownership of the walk-in refrigerator sweep and trash removal so it doesn’t get overlooked. Collect dirty linens, wash rags, and aprons daily rather than letting them pile up, because textiles can be major cross-contamination sources. Your closing checklist should cover entry door handles, server station touchscreens, salt and pepper shakers, and condiment bottles-these high-touch items require proper cleaning and sanitizing to eliminate harmful bacteria.

Weekly Deep Cleaning Assignments

Weekly deep cleaning means assigning specific zones to specific people with accountability. One staff member owns the hood and exhaust system monthly, another handles behind and under large equipment, and a third manages walk-in refrigerator sanitizing with detergent-sanitizer solution. Rotate these assignments so knowledge spreads across your team rather than depending on one person. Document who completed each task and when-this creates the paper trail that protects you during inspections and shows inspectors your team maintains consistent standards. Without written accountability, deep cleaning becomes optional and violations become inevitable.

Final Thoughts

Health code compliance in Seattle food service isn’t about passing one inspection-it’s about building systems that keep your operation safe and profitable year-round. The standards from Washington State Health Department, the inspection data available through King County, and the daily protocols we’ve covered all work together to protect your customers and your business. When you document your cleaning routines, maintain your equipment properly, and hold your team accountable through written schedules, violations become rare rather than routine.

Professional cleaning services handle the deep cleaning tasks that stretch your staff thin and often get postponed. We at Bumble Bee Cleaning Services understand the specific demands of food service environments, and our team brings certified expertise to the equipment, surfaces, and protocols that matter most during inspections. Rather than asking your cooks to spend hours behind equipment or your closing staff to tackle grease buildup they’re not trained for, outsourcing these tasks keeps your team focused on food preparation while ensuring nothing falls through the cracks.

Audit your current cleaning documentation and identify which tasks your team consistently completes and which ones slip. Then decide whether to build out your internal capacity or partner with professionals who specialize in commercial cleaning. Contact Bumble Bee Cleaning Services to explore comprehensive commercial solutions with flat-rate pricing and a quality guarantee that fits your budget and inspection goals.