Running a cleaning service in Seattle means your reputation lives or dies by the quality of every job. One missed spot or inconsistent service can cost you a customer-and the referrals that come with them.

Quality control systems stop problems before they happen. We at Bumble Bee Cleaning Services know that catching issues early, training your team right, and measuring what matters keeps clients happy and your business profitable.

How Quality Control Systems Stop Problems Before They Cost You

The moment a cleaner leaves a client’s office or home, the real test begins. Within hours, your customer inspects the work. If they find streaks on windows, dust on baseboards, or inconsistent service compared to last week, they’re already thinking about switching providers. Quality control systems catch these issues during the job or immediately after, not when your client sends an angry email. A Seattle facility using daily supervisor check-ins plus structured scheduling cut complaints by 40% and achieved inspection scores above 97%. That’s the difference between losing customers and keeping them for years.

Early Detection Saves Time and Money

Waiting for customer complaints to surface problems costs you labor, fuel, and reputation damage. Every callback drains your resources and damages trust. When you implement mobile inspection tools with photo uploads and real-time reporting, your team documents cleanliness standards instantly. A supervisor can flag incomplete restroom sanitization or missed high-touch surfaces the same day, allowing your cleaners to return and fix it before the client even notices. According to IFMA research, well-structured agreements with clear scopes reduce disputes, and that starts with catching gaps during quality inspections rather than after service delivery. Your staff learns exactly what passes inspection because they see feedback immediately, not days later in a complaint ticket.

Consistency Builds the Reputation That Brings Repeat Business

Clients want cleanliness every single visit, not just once. A 90% repeat client rate signals that reliable, consistent service keeps customers returning and cuts your acquisition costs dramatically. When your team follows the same checklist, uses the same techniques, and receives the same training across all jobs, customers notice. They trust you because they know what to expect. That consistency comes from documenting your standards in writing, training staff on those exact standards, and measuring performance against them every week. Without this system, one team delivers excellent work while another leaves spots, and your reputation suffers from the inconsistency. Digital checklists and reporting tools standardize checks across multiple sites and improve accuracy, making it impossible for quality to slip between jobs or teams.

What Happens When You Skip Quality Control

Skipping inspections and feedback loops creates blind spots. Your team doesn’t know what they’re doing wrong until a customer complains, and by then you’ve already lost trust. Inconsistent standards across your cleaning crews mean some clients receive premium service while others get mediocre results. This unpredictability drives customers away and kills your referral pipeline. When you measure performance and hold your team accountable to clear standards, you eliminate these gaps before they damage relationships.

Moving Forward With Measurement

Quality control only works when you measure what matters. Your next step involves identifying which metrics actually tell you whether your service meets customer expectations and keeps clients satisfied.

What Seattle Cleaning Services Should Actually Measure

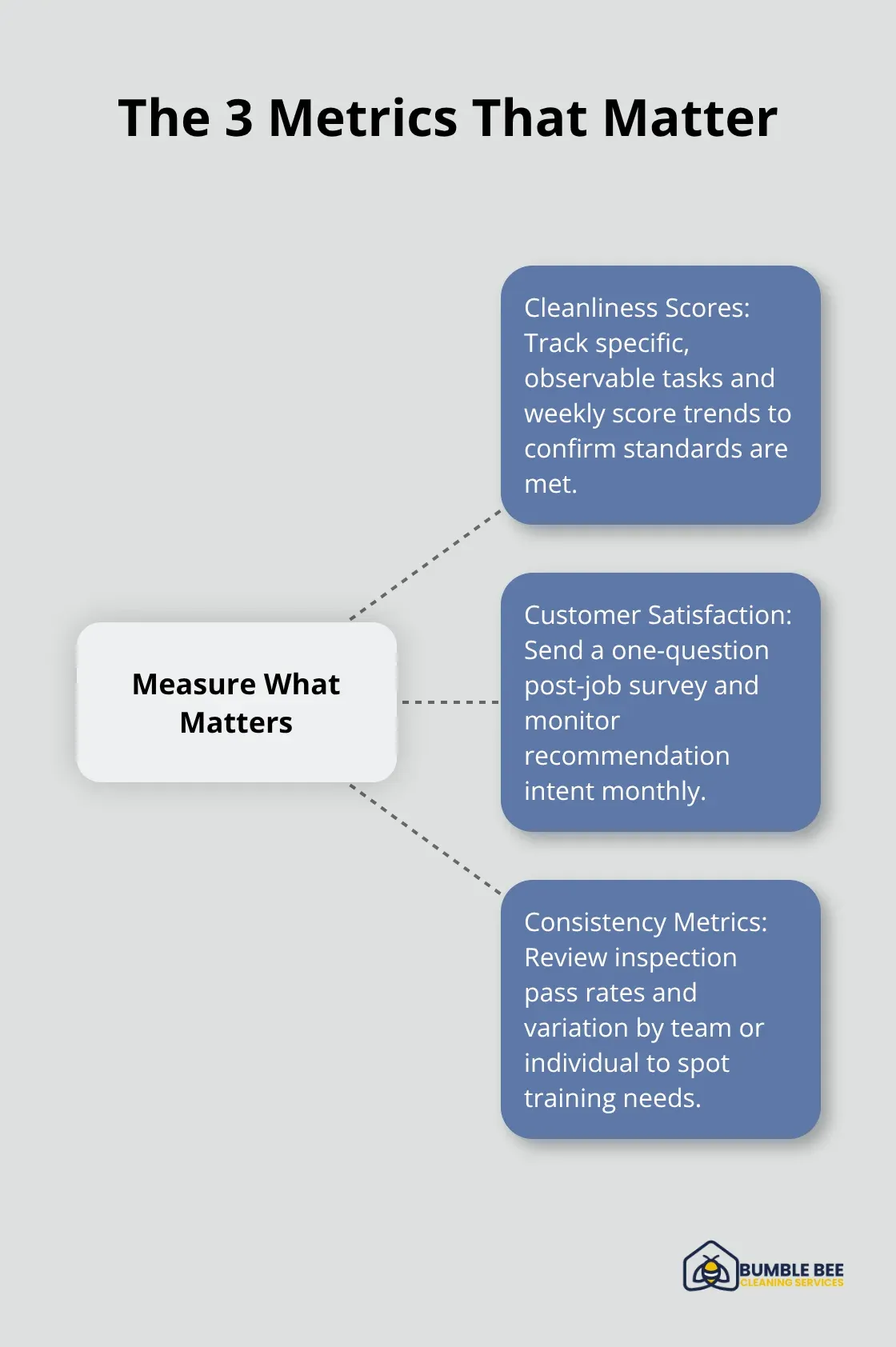

Knowing you need quality control is one thing. Knowing exactly what to measure is another. Too many Seattle cleaning businesses track vanity metrics that don’t predict whether customers will stay or leave. You need to measure three things that directly impact your bottom line: how clean your spaces actually are, whether customers plan to hire you again, and whether your team delivers the same standard every single time.

Cleanliness standards that your team can actually hit

Start with cleanliness itself. Your inspection checklist should list specific, observable tasks, not vague goals like “make it clean.” Instead, document restroom sanitization frequency, dust levels on baseboards, glass streak-free standards, and high-touch surface disinfection. Assign each task a yes-or-no completion status so your supervisor can photograph evidence and flag incomplete work the same day.

Setting clear expectations and providing the right tools and training helps your team perform better when they know exactly what passes inspection. Use a mobile app or digital tool to record these checklists in real time, not paper forms that get lost in a truck. Track your cleanliness scores weekly and watch for patterns. If certain teams consistently score 95% while others hit 87%, you have a training or accountability problem you can fix immediately.

Customer Satisfaction Scores That Predict Repeat Business

Customer satisfaction directly predicts repeat business and referrals. Surveys show that 91% of consumers read online reviews before purchasing, so your satisfaction scores matter as much to new customers as they do to current ones. After each job, send a one-question survey asking whether the customer would recommend you. Track that number monthly. If it drops below 90%, something in your service has changed, and you need to investigate fast.

Separate satisfaction from cleanliness because a customer might rate you five stars for reliability but three stars for a missed corner, and those tell different stories. This distinction helps you pinpoint exactly where service breaks down. A high cleanliness score paired with low satisfaction suggests communication or scheduling issues, while the reverse points to training gaps.

Team performance metrics that reveal your consistency problem

Team performance metrics reveal who drives your consistency. Measure task completion rates per cleaner, average time spent on each job, and inspection pass rates by individual or team. A supervisor check-in system should flag which cleaners finish work correctly on the first attempt and which ones generate callbacks.

Use your performance data to identify which team members need extra coaching. If one cleaner passes every inspection while another passes 80% of them, your top performer becomes your training standard. Invest time documenting what that person does differently, then teach it to the rest of your crew.

Connecting Your Metrics to Real Business Outcomes

Schedule monthly reviews of these three metrics together. If cleanliness scores stay high but customer satisfaction drops, your team might be rushing through jobs or missing communication. If satisfaction stays strong but team performance varies wildly, inconsistent staffing or scheduling is likely the culprit. These metrics work together to show you the full picture of where your operation stands.

Once you know what to measure, the next step is actually implementing the systems and processes that make measurement possible and actionable across your entire team.

Building Quality Control Systems That Actually Work

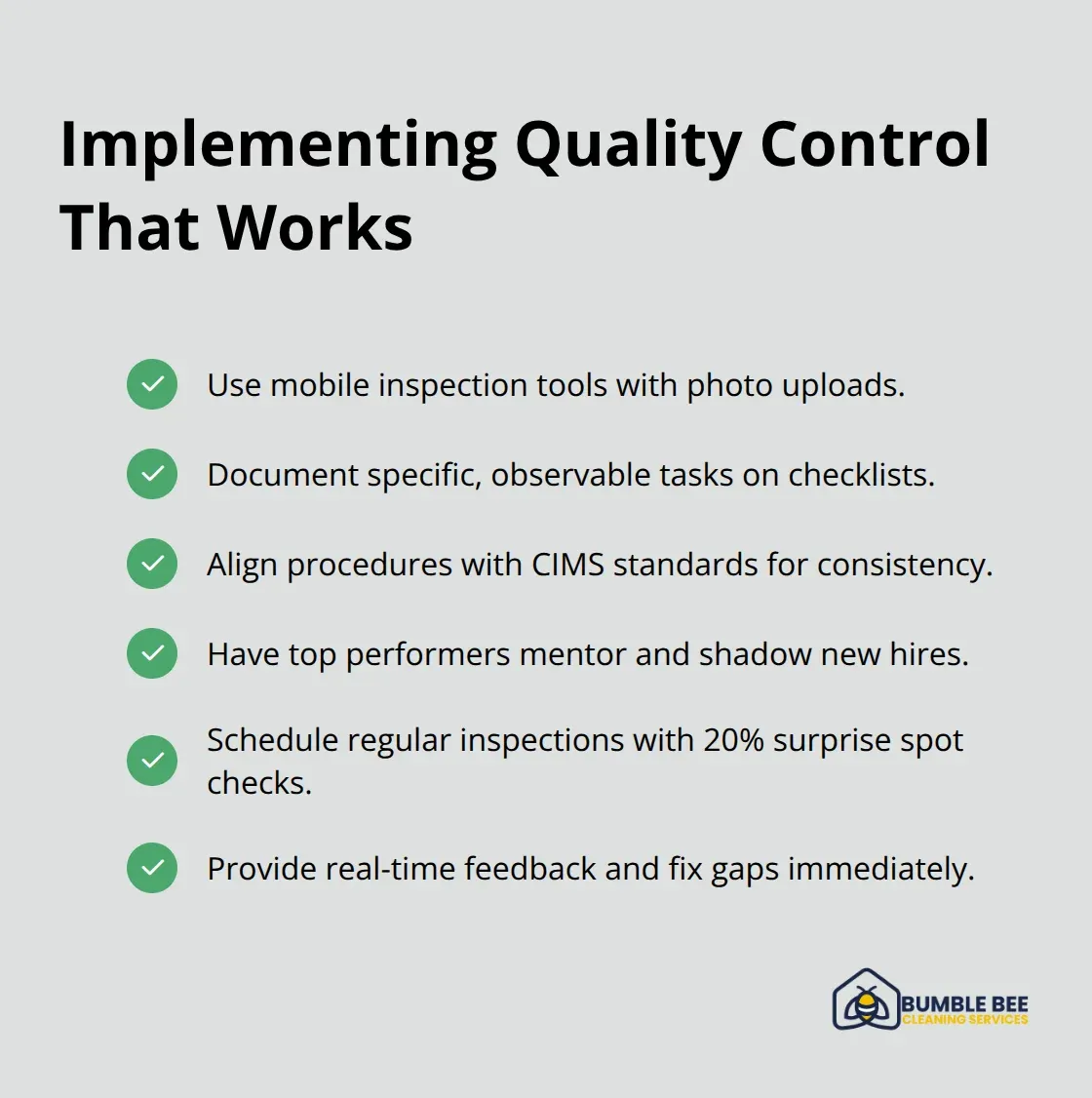

Your metrics are now clear, but knowing what to measure means nothing without systems in place to collect that data consistently. Start with documentation that your team can actually use in the field. Paper checklists get lost in truck beds and coffee spills make them unreadable. Digital inspection tools on mobile devices solve this problem immediately. Your supervisor or lead cleaner opens an app, walks through the space, and marks tasks complete or incomplete with photos attached. Real-time data flows back to your office, and you flag issues the same day instead of waiting for customer complaints.

CIMS certification signals disciplined quality control and proper disinfection product use according to industry standards, and it requires exactly this kind of documented process. Your checklist itself must be specific and observable: restroom toilets sanitized, mirrors streak-free, high-touch surfaces disinfected, baseboards dusted. Vague language like “thoroughly cleaned” does not work because two people interpret it differently.

When your team knows they will photograph their work and a supervisor will review it within hours, the quality of that work improves immediately.

Show Your Team What Passing Inspection Actually Looks Like

Training staff on your standards is pointless if they have never seen what passing inspection actually looks like. Assign your top performer-the cleaner who consistently scores 95% on inspections-to shadow new hires for their first three jobs. That person shows exactly how long each task takes, which surfaces get extra attention, and what triggers a supervisor flag. After each job, your supervisor walks through with the new hire and points out what passed and what did not, using the same photos and checklist the experienced cleaner used. This beats classroom training every time because it is real work in real spaces.

Conduct Inspections on a Schedule That Prevents Shortcuts

Schedule regular inspections weekly for the first month, then bi-weekly once performance stabilizes. Your inspection schedule should be predictable so teams cannot just clean well on inspection day-supervisors should conduct surprise spot checks on 20% of jobs to catch shortcuts. When you find gaps during inspection, address them immediately with the responsible cleaner rather than waiting for a monthly review. This feedback loop teaches faster and prevents the same mistake from happening across multiple jobs.

Final Thoughts

Quality control systems directly impact whether your Seattle cleaning business survives or thrives. When you catch problems before customers see them, train your team to consistent standards, and measure performance weekly, you keep clients satisfied and coming back. A 90% repeat client rate does not happen by luck-it comes from reliable, predictable service that customers trust, and that trust translates to referrals, longer contracts, and lower acquisition costs that protect your bottom line.

Systems save money by eliminating expensive callbacks and rework. Every time a supervisor catches an incomplete job during inspection instead of after a customer complaint, you avoid the cost of sending a team back out, the fuel, the labor, and the damage to your reputation. Well-structured agreements with clear scopes reduce disputes by up to 40% according to IFMA research, and quality control systems enforce those scopes by documenting exactly what your team delivered.

Investing in quality control keeps you competitive in Seattle’s cleaning market. Your competitors who skip inspections and rely on customer complaints to find problems will lose clients to inconsistency and poor service. You gain an advantage by implementing mobile inspection tools, training your top performers to mentor new hires, and conducting surprise spot checks that prevent shortcuts-this investment pays for itself through retained customers and reduced rework within months. Contact Bumble Bee Cleaning Services to see how we maintain pristine environments for Seattle homes and businesses with consistent results backed by our quality service guarantee.