Construction projects leave behind more than just beautiful new spaces. They create invisible health hazards that settle deep inside your HVAC system.

Dust, debris, and harmful particles from construction work contaminate your ductwork and circulate throughout your building. We at Bumble Bee Cleaning Services see firsthand how proper HVAC cleaning after construction protects your health and prevents serious respiratory issues.

What Construction Debris Does to Your HVAC System

Construction work generates multiple types of harmful debris that infiltrate your HVAC system and compromise both air quality and equipment performance. Sawdust from lumber cuts, drywall particles from installation and sanding, concrete dust from drilling operations, paint fumes and primer particles, insulation fibers, metal shavings from electrical work, and adhesive compounds all become airborne during construction. The EPA states that construction dust contains dangerous substances including silica, which presents serious lung disease hazards when people inhale it. These particles range from large visible debris to microscopic contaminants that penetrate deep into ductwork and settle on system components.

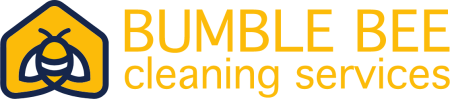

How Particles Move Through Your Building

Construction particles enter your HVAC system through air intakes and spread throughout your entire building via the ductwork network. Construction dust clogs air filters, compromises indoor air quality, and strains HVAC systems, which leads to increased energy consumption according to industry studies. Fine particles like silica and asbestos fibers remain suspended in air for hours and continuously recirculate through your ventilation system (exposing occupants to health risks). The National Air Duct Cleaners Association found in their 2012 study that contaminated ductwork significantly increases allergen levels in homes and commercial buildings.

Equipment Damage and Performance Loss

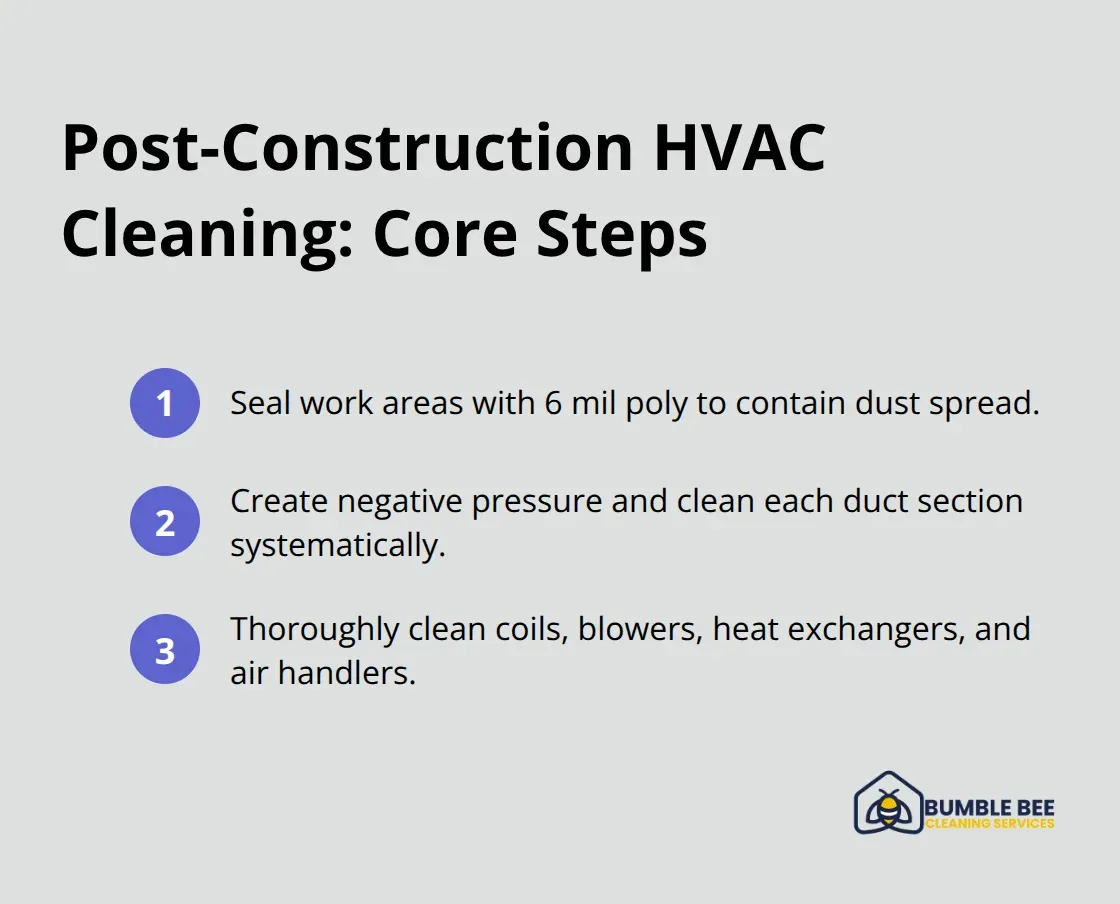

Construction debris accumulation on HVAC components decreases system performance dramatically, with studies showing reductions in energy efficiency when systems remain uncleaned after construction. Dust buildup on cooling coils, heating elements, and fan motors causes uneven temperature distribution, system malfunctions, and premature equipment failure. Professional maintenance data reveals that post-cleaning HVAC systems deliver 10% to 46% more airflow compared to contaminated systems. Construction debris blocks airflow and overworks mechanical components (leading to costly repairs and complete system replacements).

These contamination issues create serious health risks that extend far beyond equipment problems, particularly for people with existing respiratory conditions.

What Health Problems Does Contaminated Construction Dust Cause

Construction dust trapped in your HVAC system creates immediate and long-term health problems that affect everyone in your building. Silica dust, a known carcinogen according to health experts, causes severe lung infections and respiratory damage when people breathe it regularly. The U.S. Environmental Protection Agency reports that prolonged exposure to volatile organic compounds from construction materials leads to serious health issues including headaches, dizziness, and organ damage. Drywall particles and insulation fibers trigger asthma attacks, cause persistent cough, and create breathing difficulties that worsen over time. Construction debris contains cadmium, flame retardants, and polyvinyl chloride particles that accumulate in your lungs and bloodstream.

Respiratory System Damage and Breathing Problems

Construction dust exposure causes immediate respiratory symptoms including chest tightness, wheezing, and difficulty breathing that can become permanent without proper treatment. Workers and building occupants develop chronic obstructive pulmonary disease, lung scarring, and reduced lung capacity from inhaled contaminated air. The EPA emphasizes that control of indoor air pollutants like construction dust produces measurable health improvements within weeks of cleaning. Studies show that people with existing respiratory conditions experience more severe symptoms when exposed to construction-contaminated indoor air compared to clean environments.

Allergic Reactions and Immune System Stress

Construction particles trigger severe allergic reactions including skin rashes, eye irritation, and sinus inflammation that persist long after construction ends. The National Air Duct Cleaners Association’s research demonstrates that contaminated ductwork increases household allergen levels compared to clean systems. People develop new allergies and sensitivities to common substances after extended exposure to construction dust through their HVAC systems. Children face higher risks because their developing immune systems cannot effectively process these toxic particles, which leads to lifelong respiratory problems and compromised health.

Long-Term Health Consequences

Extended exposure to construction-contaminated air creates permanent health damage that affects quality of life for years. Medical research shows that people who live or work in buildings with contaminated HVAC systems develop chronic respiratory conditions at higher rates than those in clean environments. Construction dust particles remain active in your system for months after project completion, continuously exposing occupants to health hazards. These ongoing health risks make professional HVAC cleaning after construction an essential step that protects your family and employees from serious medical complications.

How Does Professional HVAC Cleaning Work

Professional post-construction HVAC cleaning requires specialized assessment techniques that identify contamination levels and determine the exact approach your system needs. Certified technicians begin with comprehensive ductwork inspection and use high-powered cameras and air quality tests to locate debris accumulation points and assess contamination severity. Professionals examine all system components including supply and return ducts, air handlers, coils, and filtration systems to map contamination patterns throughout your building. This assessment identifies specific health hazards like silica particles, metal shavings, and chemical residues that standard methods cannot remove effectively.

Advanced Equipment and Proven Techniques

Professional HVAC cleaners use powerful truck-mounted vacuum systems that generate negative pressure up to 16,000 cubic feet per minute, which removes embedded construction debris that household equipment cannot reach. HEPA-filtered vacuums capture particles as small as 0.3 microns, including dangerous silica dust and asbestos fibers that pose serious health risks. Specialized brush systems and compressed air tools dislodge stubborn debris from ductwork walls and system components without damage to equipment. Studies show that professional cleaners restore HVAC systems to deliver 10% to 46% more airflow compared to contaminated systems, which directly improves energy efficiency and reduces costs.

Complete System Restoration Process

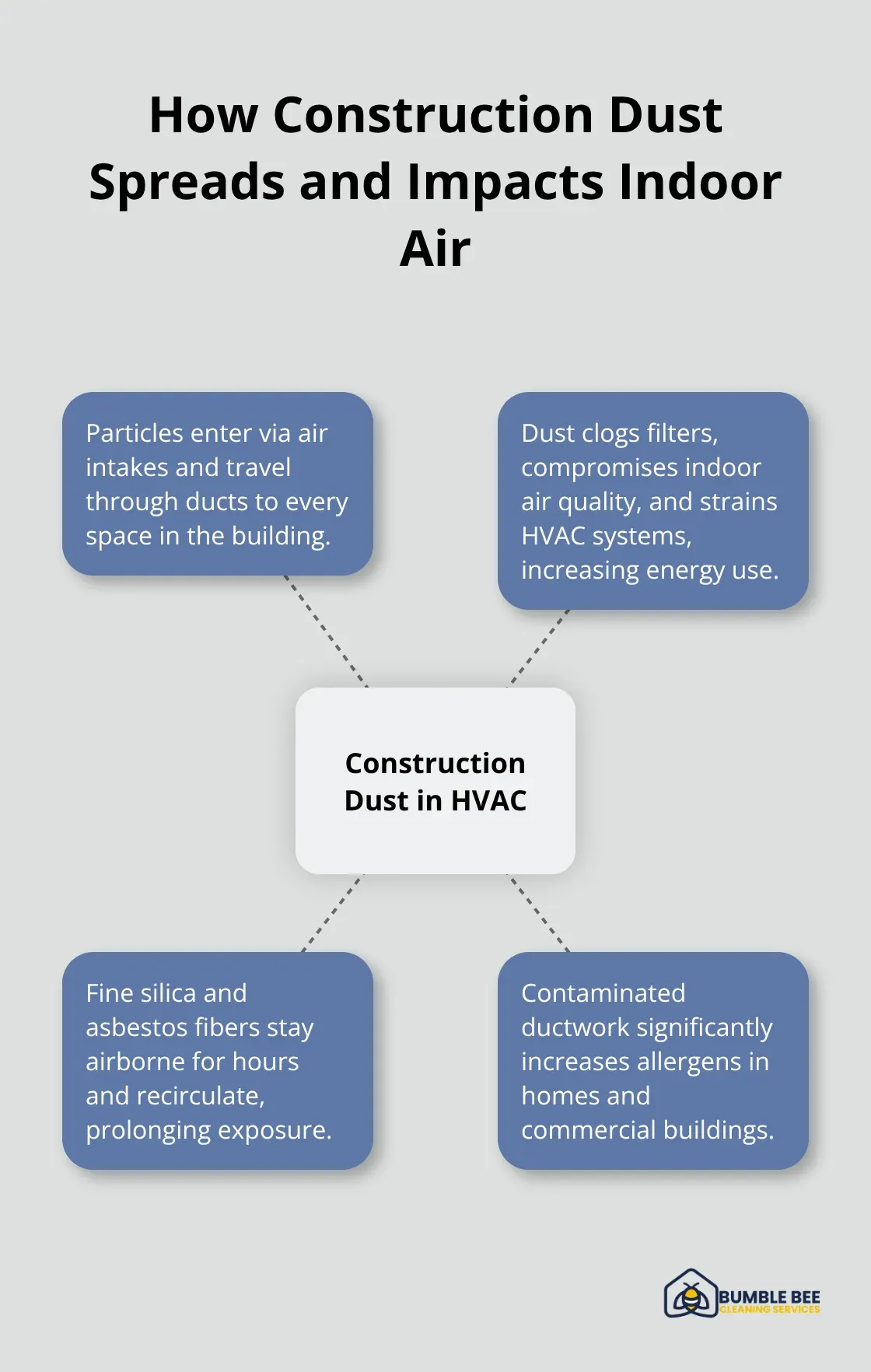

The process takes 4 to 8 hours for residential systems and up to 16 hours for large commercial buildings, depending on contamination levels and system complexity. Technicians seal off work areas with 6 mil poly sheeting to prevent dust spread during operations, then systematically clean each duct section with negative pressure containment. All system components receive thorough attention including evaporator coils, blower assemblies, heat exchangers, and air handlers that accumulate the heaviest debris loads.

Final Steps and System Protection

Professionals complete the process with sanitization treatments that use EPA-approved antimicrobial solutions and install high-efficiency filters that prevent future contamination buildup. Technicians test airflow rates and verify that all debris has been removed from accessible areas, ensuring your system operates at peak performance. The final inspection confirms that your HVAC system meets indoor air quality standards and protects occupant health from construction-related contaminants.

Final Thoughts

Professional post-construction HVAC cleaning delivers measurable health improvements that protect your family and employees from dangerous respiratory conditions. Clean systems eliminate silica dust, construction debris, and toxic particles that cause asthma, allergies, and lung damage. Studies show that proper HVAC cleaning reduces allergen levels and improves indoor air quality within weeks of service completion.

Professional cleaning prevents costly equipment failures and extends system lifespan when technicians remove debris that clogs components and reduces efficiency. Research demonstrates that cleaned systems deliver 10% to 46% more airflow and achieve energy savings of 41% to 60% compared to contaminated equipment. These improvements translate to lower utility bills and fewer repair costs over time (which benefits both residential and commercial property owners).

We at Bumble Bee Cleaning Services understand that post-construction HVAC cleaning protects your investment and health. Our team uses specialized equipment and proven techniques to restore your system to peak performance. Professional post-construction cleaning removes health hazards that DIY methods cannot reach and provides the thorough restoration your HVAC system needs after construction work.