Dust control is a critical aspect of construction projects in Seattle, affecting both worker safety and environmental quality. At Bumble Bee Cleaning Services, we understand the challenges contractors face in managing dust on their sites.

This guide will walk you through Seattle’s dust control regulations, effective strategies, and innovative technologies to help you master dust management. By implementing these practices, you’ll not only comply with local standards but also create a cleaner, safer work environment for everyone involved in your project.

What Are Seattle’s Dust Control Rules?

Seattle’s Dust Control Requirements

Seattle takes dust control seriously for construction projects. The Seattle Department of Construction and Inspections (SDCI) requires all construction sites to implement dust control measures. These measures must be in place before work starts and continue throughout the project. The primary goal is to prevent dust from escaping the site and affecting nearby areas.

Key Regulations and Standards

Seattle’s construction dust control regulations align with the Puget Sound Clean Air Agency’s requirements. These rules state that visible dust emissions must not extend beyond the property line. To comply, contractors need to:

- Use water sprays

- Cover stockpiles

- Limit vehicle speeds on unpaved areas

Penalties for Non-Compliance

The SDCI doesn’t take dust control violations lightly. Failing to manage dust can result in significant consequences:

- Fines up to $5,000 per day

- Potential work stoppage until proper measures are implemented

These penalties (which can quickly add up) highlight the importance of a robust dust management plan.

Impact on Post-Construction Cleaning

Proper dust control during construction significantly impacts post-construction cleaning. It creates a safer, cleaner environment for everyone involved in and around the project. Companies that specialize in post-construction cleaning often notice the difference between sites that prioritized dust control and those that didn’t.

Preparing for Your Next Steps

Understanding Seattle’s dust control rules is just the first step. The next crucial phase involves implementing effective strategies to manage dust on your construction site. Let’s explore some proven techniques that will help you maintain compliance and create a cleaner work environment.

How to Control Dust on Seattle Construction Sites

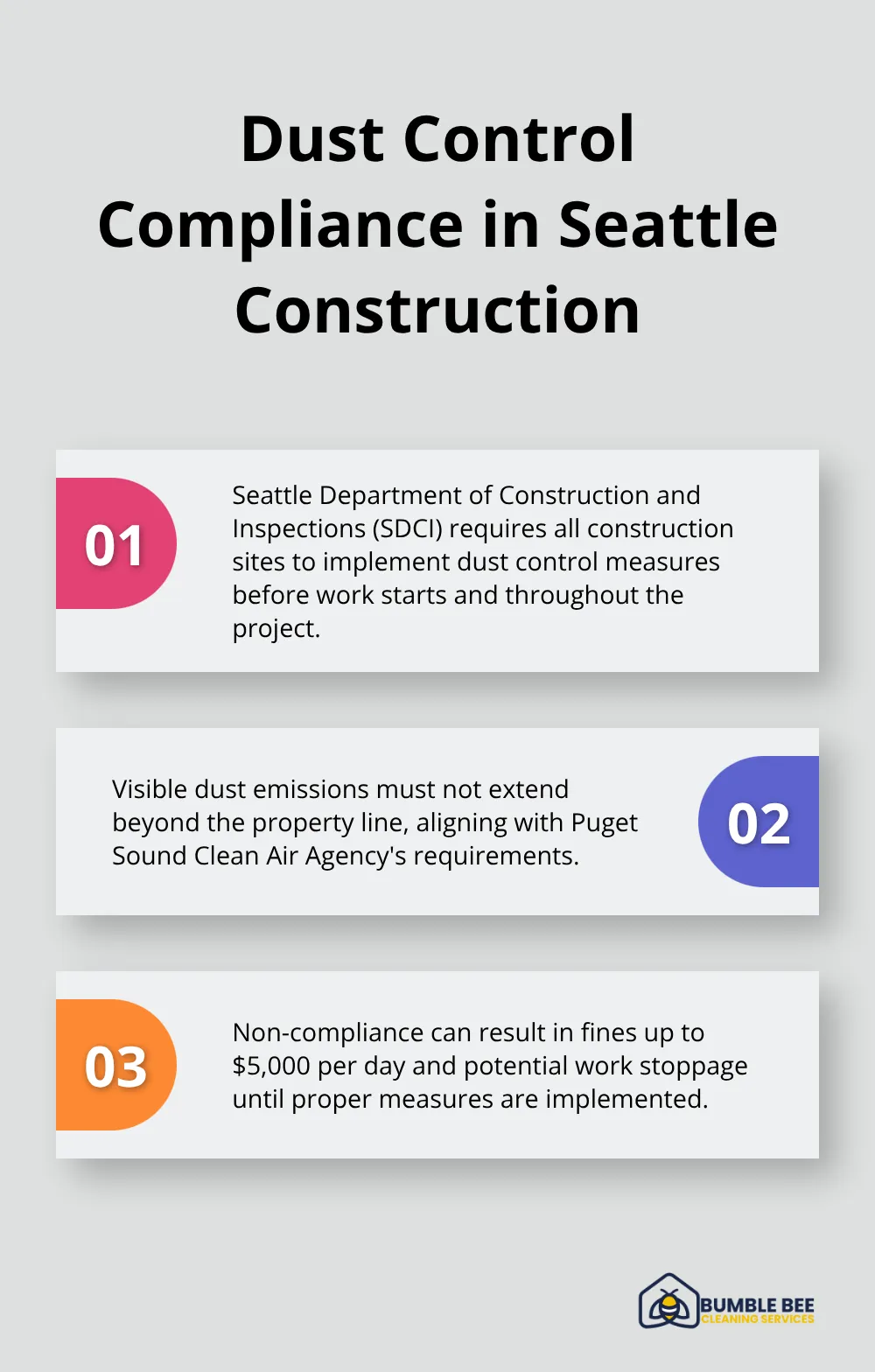

Water Suppression: Your First Line of Defense

Water serves as one of the most effective tools for dust control. When it rains, stormwater runoff picks up harmful substances from parking lots, roofs, streets, sidewalks and construction sites. To prevent this:

- Apply water before, during, and after dust-generating activities

- Focus on high-traffic areas and material stockpiles

- Adjust water application based on weather conditions

It’s important to strike a balance, as overwatering can lead to muddy conditions (which create their own set of problems).

Creating Physical Barriers

Physical barriers contain dust within your construction site. Install solid fencing or windscreens around the perimeter of your project. These barriers should be:

- At least 6 feet high

- Made of materials like plywood or heavy-duty plastic sheeting

- Securely fastened to withstand wind and weather

For added effectiveness, consider using misting systems along the top of your barriers to catch any escaping dust.

Smart Material Handling and Storage

Your approach to material handling and storage can significantly impact dust control. Follow these best practices:

- Cover all stockpiles of sand, gravel, or soil with tarps when not in use

- Minimize drop heights when loading or unloading materials

- Use enclosed chutes for debris removal from upper floors

- Store fine materials like cement in silos or enclosed containers

Implementing Dust Suppression Technologies

Modern dust suppression technologies can enhance your dust control efforts. Some effective options include:

- Fog cannons (which create a fine mist to capture airborne particles)

- Dust-binding agents (applied to soil to create a crust that prevents dust from becoming airborne)

- Vacuum-equipped power tools (to capture dust at the source)

These technologies, when used in combination with traditional methods, can dramatically reduce dust levels on your site.

Training and Awareness

Effective dust control requires a team effort. Train your workers on the importance of dust management and the specific techniques you’re using on site. Regular toolbox talks can help reinforce good practices and keep everyone aligned with your dust control goals.

The next step in mastering dust control involves exploring innovative technologies that can take your efforts to new heights. Let’s examine some cutting-edge solutions that are revolutionizing dust management on construction sites.

Cutting-Edge Dust Management Tech

Construction dust control has evolved significantly in recent years. New technologies transform dusty sites into cleaner, safer environments. Let’s explore some game-changing innovations that reshape dust management in Seattle’s construction industry.

HEPA Filtration: The Gold Standard

High-efficiency particulate air (HEPA) filtration systems revolutionize air quality on construction sites. These powerhouses remove 99.97% of airborne particles, which significantly improves indoor air quality post-renovation.

Construction sites that use HEPA air scrubbers experience a noticeable improvement in air quality. Workers report fewer respiratory issues, and neighboring businesses have fewer complaints about dust. Professional cleaning services often utilize HEPA filtration systems to ensure thorough post-construction cleanup.

Smart Dust Collection Systems

Modern dust collection equipment outperforms brooms and dustpans. Today’s vacuum systems with automatic filter cleaning maintain suction power throughout the workday, which increases productivity and dust capture rates.

A study by the National Institute for Occupational Safety and Health (NIOSH) found that vacuum-assisted tools can reduce respirable dust levels by up to 90% compared to uncontrolled tools. This dramatic reduction improves air quality and extends equipment life by keeping it cleaner.

Real-Time Air Quality Monitoring

Real-time air quality monitoring tools provide instant feedback on dust levels, which allows site managers to adjust their strategies quickly. These systems use sensors to measure particulate matter concentrations and can send alerts when levels exceed predetermined thresholds.

In Seattle, additional air quality monitoring sites are planned for 2024, with community engagement playing a role in their implementation.

Fog Cannons and Misting Systems

Fog cannons and misting systems create a fine water mist that captures airborne dust particles. These systems prove particularly effective in large open areas or at the perimeter of construction sites. They can cover extensive areas and adapt to changing wind conditions.

Dust Suppression Coatings

Innovative dust suppression coatings form a thin, flexible crust over exposed soil or stockpiles. These coatings (often made from biodegradable materials) prevent wind erosion and dust generation. They can last for several months, which reduces the need for constant reapplication.

Final Thoughts

Dust control is a fundamental aspect of responsible construction in Seattle. Construction companies that implement effective dust management strategies comply with local regulations and create safer, cleaner work environments. These practices improve worker health, enhance community relations, and reduce environmental impact.

A comprehensive dust control plan requires a multi-faceted approach. Companies should understand Seattle’s dust control regulations and integrate them into project planning from the start. They should use traditional methods like water suppression and physical barriers alongside innovative technologies such as HEPA filtration systems and real-time air quality monitoring.

Dust control continues after construction ends. Post-construction cleaning ensures the final product is safe and ready for occupancy. For expert post-construction cleaning services that complement your dust control efforts, partner with Bumble Bee Cleaning Services. Our team uses eco-friendly products and advanced techniques to deliver exceptional results (ensuring your project shines from start to finish).