A clean factory floor isn’t just about appearances. It’s the foundation of a safe workplace where your team can focus on their jobs without unnecessary risks.

At Bumble Bee Cleaning Services, we’ve seen firsthand how factory cleaning directly impacts worker safety and compliance. When you partner with professionals who understand industrial environments, you’re investing in fewer accidents, better health outcomes, and a stronger safety culture.

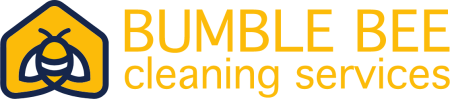

How Cleanliness Directly Prevents Worker Injuries

A dirty factory floor doesn’t just look bad-it actively injures people. Falls account for 38.5% of construction and industrial fatalities, and most of these happen on contaminated, cluttered surfaces. Spilled liquids, scattered debris, and dust buildup transform your production floor into a hazard zone. Regular floor maintenance eliminates these risks. Workers need solid footing throughout their shifts, and systematic removal of wet floors, oil residue, and loose materials provides exactly that.

A clean floor means fewer slip-and-fall incidents, lower workers’ compensation claims, and employees who actually show up to work instead of recovering from preventable injuries.

The Respiratory Threat You Can’t See

Airborne dust in factories contains toxic substances like crystalline silica that cause serious respiratory diseases. These exposures accumulate over time-small daily inhalations add up over months and years to create serious health problems for your workforce. HEPA vacuums capture 99.97% of particles down to 0.3 microns, but only if cleaning happens consistently and thoroughly. Your employees might not complain about dust today, but respiratory irritation, persistent coughing, and irritated eyes signal that contamination is building. Professional cleaning removes this invisible threat before it settles into your workers’ lungs.

Equipment That Functions Safely

Dust and debris buildup inside machinery causes overheating, electrical faults, and component failures that put maintenance workers at serious risk. Contaminated electrical panels and worn equipment guards become fire hazards or create sudden breakdowns that injure people during emergency repairs. Regular cleaning of these systems prevents catastrophic failures and maintains stable operating conditions. When your production equipment runs clean, it runs predictably, reducing the emergency situations that lead to worker injuries during unplanned maintenance or equipment failure.

Why Professional Expertise Matters

Industrial environments demand specialized knowledge that standard cleaning cannot provide. Factories contain hazards that require trained teams who understand equipment layouts, electrical systems, and material-specific risks. Professional cleaners bring the right equipment, safety protocols, and experience to handle these complexities without creating new dangers. Your team can focus on production while experts handle the cleaning that protects them.

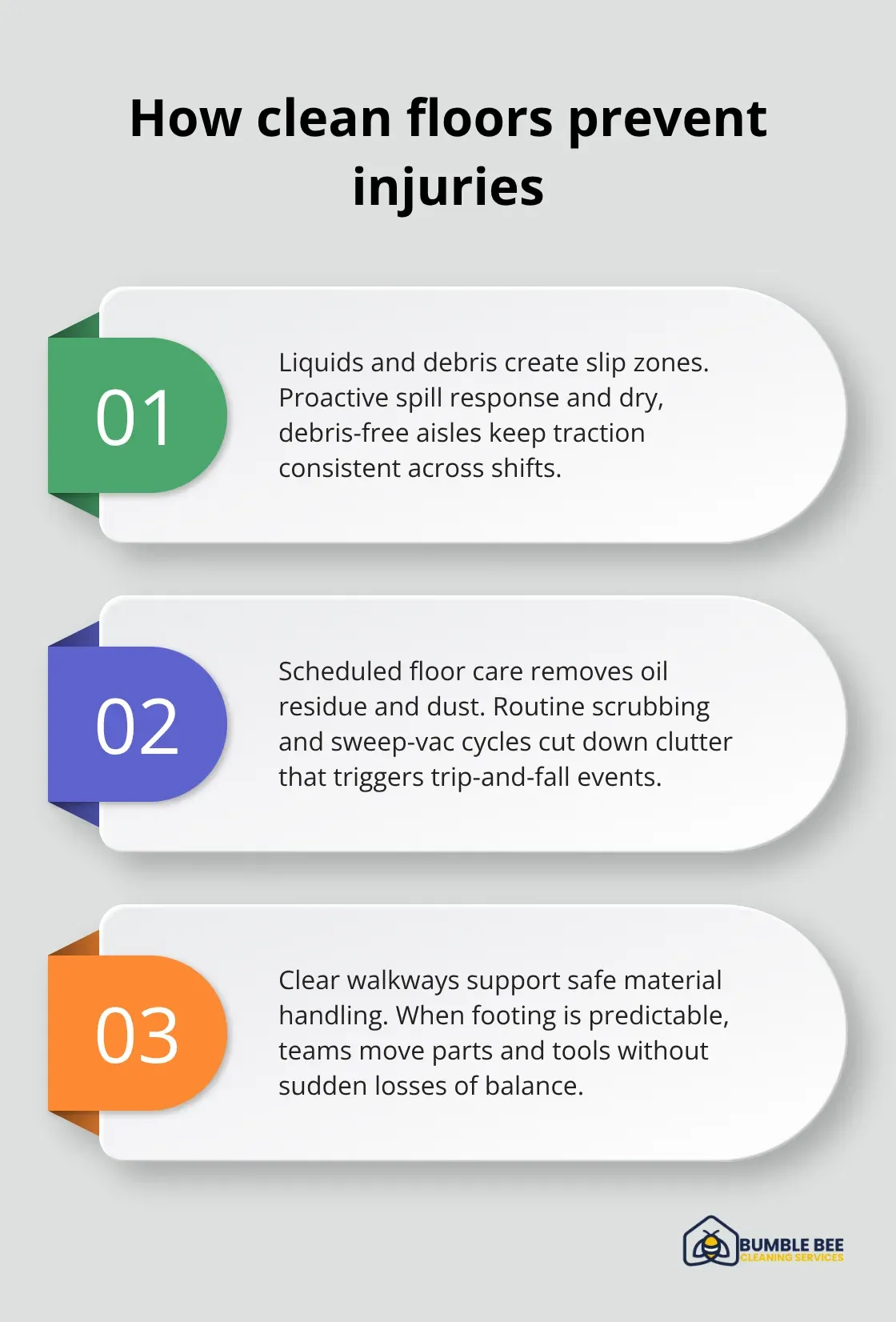

Building Compliance Into Your Daily Cleaning Routine

OSHA doesn’t require factories to be sterile, but it does mandate that workplaces remain clean enough to prevent hazards. The difference between passing an inspection and failing one often comes down to whether your cleaning happens on a schedule or sporadically. Factories that implement systematic cleaning programs reduce workplace incidents significantly because consistency matters more than intensity. You need a documented schedule that covers all production areas, high-touch surfaces, electrical equipment, and machinery on intervals that match your actual operations. If your facility runs 24/7, your cleaning cannot happen once a week. OSHA enforcement targets facilities where cleaning lapses correlate with injury spikes, so auditors will ask to see your cleaning logs, maintenance records, and any documentation showing when tasks were completed and by whom. The moment you stop documenting your cleaning activities, you’ve stopped proving compliance.

Digital checklists outperform paper ones because they create timestamped records that show auditors exactly what happened and when. Many facilities use platforms that generate shareable safety reports automatically, eliminating the excuse of lost paperwork during inspections.

Documentation That Protects You

Your cleaning records become your defense during OSHA investigations. When an injury occurs, inspectors will ask whether the area was clean and maintained properly. If you have no documentation, you’re essentially admitting you don’t know. Detailed records show that you identified hazards, took corrective action, and maintained consistency over time. Each checklist entry should specify the area cleaned, the date, the time, the person responsible, and any issues found or addressed. This level of detail transforms cleaning from an afterthought into a documented safety control. Facilities that maintain meticulous cleaning documentation experience fewer citations because they can prove their commitment to worker protection. The investment in a tracking system pays for itself the moment it prevents a single violation notice.

Why Consistency Creates Safety Culture

Factories where workers see daily cleaning happening develop different attitudes about hazards than facilities where cleaning happens occasionally. When your team watches management prioritize cleanliness every single day, they internalize the message that safety matters. Workers report spills and debris faster because they know someone will address them quickly. Maintenance staff take equipment care seriously because they see the facility being maintained as a whole. This cultural shift reduces incidents more effectively than any single cleaning intervention because it changes how your workforce thinks about their environment. Consistency also helps your team spot problems early before they become hazards that injure people or damage equipment.

Moving From Documentation to Professional Standards

Your internal cleaning efforts form the foundation, but industrial environments often contain hazards that require specialized knowledge and equipment. Professional cleaning teams bring trained expertise in handling electrical systems, machinery contamination, and material-specific risks that standard cleaning cannot address. The next section explores how professional factory cleaning services in Seattle provide the specialized capabilities your facility needs to maintain compliance and protect your workers at every level.

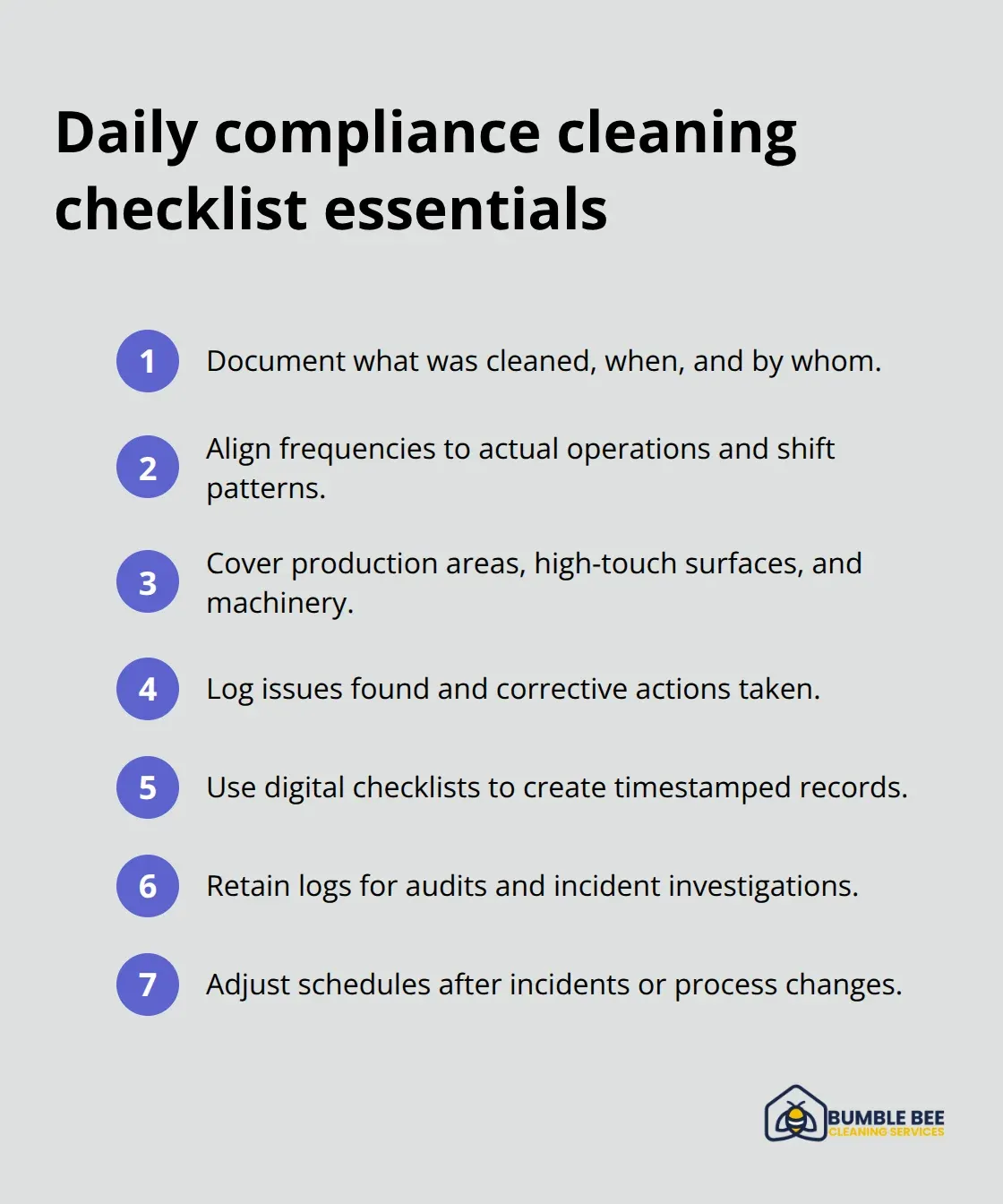

Why Professional Factory Cleaning Outperforms Internal Approaches

Factories operate under constraints that standard cleaning cannot address. Your production schedule doesn’t pause for deep cleaning, your equipment contains hazards that untrained staff shouldn’t approach, and your compliance documentation demands consistency that internal teams struggle to maintain. Professional factory cleaning services bring specialized equipment, trained personnel, and systematic protocols designed specifically for industrial environments where one mistake creates liability.

Specialized Equipment Your Facility Likely Hasn’t Invested In

HEPA-filtered vacuums capture 99.97% of particles down to 0.3 microns, pressure washing systems remove oil and chemical residue without damaging electrical components, and degreasing equipment handles food processing or automotive manufacturing contamination. These investments represent significant capital expenses that most facilities cannot justify for occasional use. Professional teams own and maintain this equipment, which means you access industrial-grade cleaning capabilities without the upfront cost.

Professional cleaners understand which methods work for different production areas without interfering with your operations. A food manufacturing floor requires different protocols than a metal fabrication shop, and a facility storing hazardous materials demands knowledge of proper disposal procedures that RCRA regulations mandate. Your internal maintenance crew focuses on keeping equipment running, not mastering industrial cleaning techniques. When you outsource factory cleaning to professionals who specialize in manufacturing environments, you eliminate the risk of untrained workers damaging sensitive machinery, creating electrical hazards, or improperly handling hazardous materials.

Customized Plans That Match Your Actual Operations

Professional services conduct site assessments that identify which areas present the highest safety risks, which equipment requires regular cleaning to prevent malfunctions, and which surfaces demand priority attention for compliance. This targeting means your investment focuses on hazards that actually threaten your workers rather than treating every surface equally. A 24/7 production operation needs cleaning protocols that work around continuous manufacturing, not a standard Monday-to-Friday approach. Professional cleaners adapt their schedules to your facility’s reality instead of forcing your operations to fit a generic template.

The Financial Case for Professional Cleaning

A single workplace injury costs manufacturers significant expenses in direct and indirect costs, while professional cleaning contracts typically cost far less. Reducing slip-and-fall incidents alone justifies the expense because workers’ compensation claims, lost productivity, and potential OSHA citations add up quickly. Professional cleaners also prevent equipment failures that trigger emergency maintenance situations where injuries happen most frequently. Your facility operates more safely, maintains better compliance documentation, and avoids the expense of managing injuries when you partner with experienced cleaning services that understand industrial hazards and the practical realities of manufacturing operations.

Final Thoughts

Factory cleaning directly protects your workers from the hazards that cause injuries, respiratory disease, and equipment failures. Facilities that maintain systematic cleaning schedules experience fewer slip-and-fall incidents, lower respiratory complaints, and better compliance outcomes. Your team deserves a workplace where they can focus on their jobs without unnecessary risks from contaminated floors, airborne dust, or malfunctioning equipment caused by debris buildup.

Professional factory cleaning services accelerate these safety improvements by bringing specialized equipment, trained expertise, and documented protocols that your internal team cannot replicate alone. When you partner with experienced cleaners who understand industrial environments, you eliminate the uncertainty about which areas need priority attention, how often cleaning should happen, and whether your current approach meets OSHA standards. Professional teams also create the timestamped documentation that protects you during inspections and investigations, transforming cleaning from an informal activity into a verifiable safety control.

A single workplace injury costs far more than a professional cleaning contract, and preventing equipment failures that trigger emergency maintenance situations saves money while protecting workers. We at Bumble Bee Cleaning Services develop customized cleaning plans that match your production schedule and target the hazards that actually threaten your workers. Contact us today to discuss how professional factory cleaning can strengthen your safety culture and protect your team.