Construction cleanup transforms chaotic job sites into pristine spaces ready for occupancy. The process requires specific knowledge, proper equipment, and systematic approaches to handle debris safely.

We at Bumble Bee Cleaning Services have seen countless Seattle projects where inadequate cleanup created costly delays and safety issues. This guide provides the essential steps and professional insights you need for successful post-construction cleanup.

What Cleanup Challenges Await After Construction

Post-construction sites contain far more than visible debris. Seattle construction projects typically generate substantial waste material according to the National Association of Home Builders. This waste includes drywall dust, wood scraps, metal shavings, concrete fragments, and adhesive residues that settle into every corner and crevice.

Fine particulate matter poses the greatest challenge because standard vacuums cannot capture particles smaller than 0.3 microns. Construction dust contains hazardous substances including silica, lead, and asbestos according to OSHA guidelines. These microscopic particles require specialized equipment to remove safely.

Health Risks Demand Immediate Action

Construction dust significantly impacts indoor air quality and respiratory health. The Environmental Protection Agency identifies volatile organic compounds from paint, sealants, and adhesives as major contributors to indoor air pollution. These particles remain airborne for hours after construction ends, settle on surfaces, and infiltrate HVAC systems.

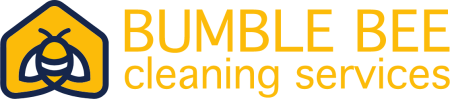

Workers and future occupants face serious health risks without proper cleanup protocols. Industrial-grade HEPA vacuums capture 99.97% of particles as small as 0.3 microns, making them essential for safe cleanup operations. Standard household equipment simply cannot handle this level of contamination.

Timeline Factors Create Additional Pressure

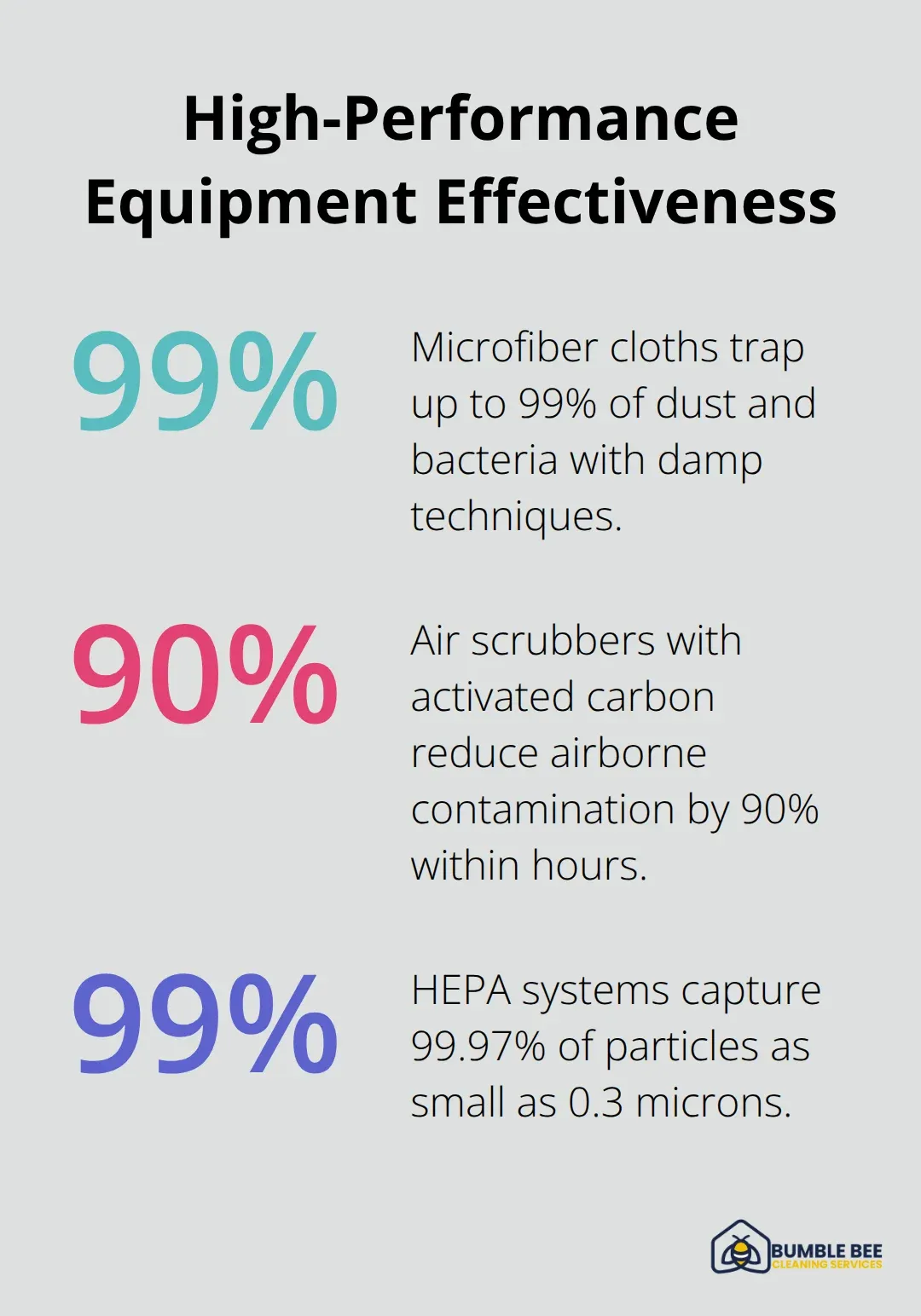

Seattle’s climate adds complexity to cleanup schedules. Rain and moisture can turn construction dust into stubborn mud, which extends cleanup time by 30-50%. Start cleanup immediately after construction completion to prevent debris from hardening or becoming embedded in surfaces.

Professional cleaning teams complete thorough cleanup 3 times faster than DIY efforts according to American Cleaning Institute research. Plan 2-3 days for residential projects and up to one week for commercial spaces. Delayed cleanup leads to permanent stains, equipment damage, and failed final inspections that cost thousands in project delays.

Material-Specific Challenges Require Different Approaches

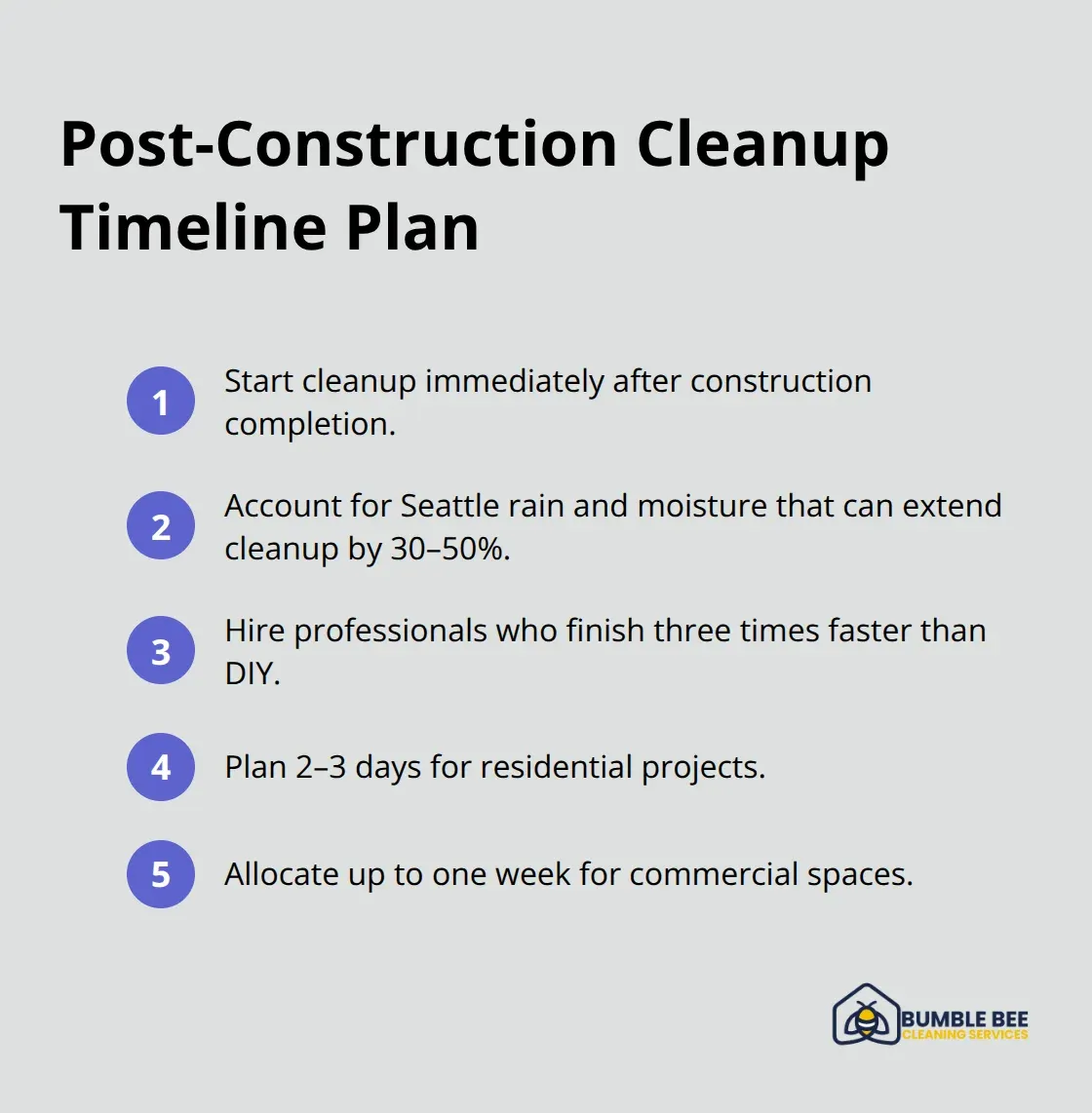

Different construction materials create unique cleanup challenges. Drywall dust creates a fine powder that coats every surface and requires multiple cleaning passes. Paint overspray bonds to windows and fixtures (requiring specialized solvents for safe removal). Concrete dust embeds deeply into porous surfaces and demands aggressive extraction methods.

Wood shavings and metal fragments pose cutting hazards during manual cleanup. Adhesive residues from flooring and fixtures resist standard cleaners and need heat application or chemical solvents. Each material type demands specific tools and techniques for effective removal.

The right equipment and systematic approach make the difference between successful cleanup and costly mistakes. Professional-grade tools and proven methods address these challenges efficiently and safely.

What Equipment Do You Actually Need

Industrial-grade HEPA vacuums form the foundation of effective post-construction cleanup because they capture microscopic particles that standard equipment misses. These vacuums cost between $500-$1,200 but remove 99.97% of particles as small as 0.3 microns. Rent professional units for $50-$80 per day rather than purchase household vacuums that redistribute dust into the air.

Microfiber cloths trap up to 99% of dust and bacteria when you use damp techniques. Air scrubbers with activated carbon filters process up to 2,000 cubic feet of air per minute and reduce airborne contamination by 90% within hours.

Safety Equipment Protects Your Health

OSHA mandates specific protective equipment for construction cleanup due to hazardous dust exposure. N95 respirators provide minimum protection, but P100 masks filter 99.97% of airborne particles and offer superior safety for extended cleanup periods (especially in Seattle’s dusty conditions).

Safety goggles prevent eye irritation from debris, while nitrile gloves resist chemicals and adhesive residues. Heavy-duty work boots with puncture-resistant soles protect against metal fragments and sharp objects embedded in debris.

Surface-Specific Products Prevent Damage

pH-neutral cleaners preserve hardwood floors and natural stone surfaces that acidic or alkaline products can permanently damage. Warm water mixed with dish soap removes paint overspray and adhesive residues without harsh chemicals that void material warranties.

Commercial-grade glass cleaners paired with microfiber cloths create streak-free windows and eliminate construction film buildup. Heat guns soften stubborn adhesive residues for safe removal without surface damage (particularly effective on flooring adhesives).

Industrial floor buffers restore shine to sealed concrete and reduce cleanup time by 50% compared to manual methods. These tools handle the heavy-duty work that manual scrubbing cannot accomplish effectively.

The right equipment sets the stage for systematic cleanup execution. Next, you need a proven process that tackles debris removal in the correct sequence to maximize efficiency and safety.

How Do You Execute the Cleanup Process

Begin debris removal from the farthest room and work toward the exit to prevent recontamination of cleaned areas. Remove large debris first with heavy-duty trash bags and debris containers. Construction projects generate significant waste materials that require proper disposal planning. Sort materials into recyclable categories including metal, wood, and drywall to reduce landfill contributions by up to 30% according to the Seattle Department of Construction and Inspections.

Surface Deep Cleaning Eliminates Hidden Contaminants

Attack surfaces systematically starting with ceilings and work downward to prevent dust redistribution onto cleaned areas. Use damp microfiber techniques that trap 99.5% of particles compared to dry methods that simply move dust around. Pay special attention to air vents and light fixtures where construction debris accumulates and impacts indoor air quality.

The Indoor Air Quality Association emphasizes that HVAC system cleaning post-construction prevents contaminated air circulation throughout the space. Apply warm water and dish soap solutions to remove paint overspray and adhesive residues from windows and fixtures. Heat guns soften stubborn adhesive materials for safe removal without surface damage (particularly effective on flooring adhesives).

Floor Treatment Requires Specialized Approaches

Different flooring materials demand specific techniques for effective cleanup. Hot water extraction methods for carpets remove up to 98% of dirt and allergens according to the Carpet and Rug Institute. Steam clean carpets thoroughly to eliminate embedded construction dust that standard vacuums cannot reach.

For hardwood floors, use pH-neutral cleaners that preserve the wood’s finish and prevent damage. Industrial floor buffers restore shine to sealed concrete and reduce cleanup time by 50% compared to manual scrubbing methods.

Final Inspection Prevents Costly Oversights

Conduct room-by-room walkthroughs with bright lighting to identify missed spots and residual dust. Check behind appliances, inside cabinets, and under fixtures where debris often hides. Test all cleaned surfaces with white cloths to detect remaining dust particles.

Industrial air movers reduce floor drying time by 50% and prevent moisture-related issues that can lead to mold growth in Seattle’s humid climate. Verify that all construction residues have been removed from grout lines, window tracks, and door frames (these areas often trap the most stubborn debris). For comprehensive guidance on post-construction cleaning best practices, consider following established protocols that ensure thorough results.

Final Thoughts

Professional construction cleanup transforms hazardous job sites into safe, livable spaces while protecting your investment. Industrial-grade equipment removes 99.97% of harmful particles that standard methods cannot address. This thorough approach prevents respiratory health issues and eliminates costly delays from failed inspections.

Seattle projects face unique challenges from moisture and fine dust that demand specialized knowledge. Professional services complete construction cleanup three times faster than DIY efforts while using industrial HEPA vacuums and eco-friendly products that protect both occupants and the environment (particularly important in Seattle’s climate conditions). The investment in thorough cleanup pays dividends through improved indoor air quality, preserved surface integrity, and faster occupancy timelines.

We at Bumble Bee Cleaning Services bring years of experience to Seattle construction projects. Our team uses professional-grade equipment and eco-friendly products. The difference between amateur and professional cleanup becomes evident in the final results and long-term building health.